Looking for a machine that can weld, clean, and cut—all in one? A 3-in-1 laser cleaning machine saves time, space, and cost, making it ideal for workshops and factories. In this guide, we’ve picked the 6 best models to help you choose the right one with ease.

Introduction to 3-in-1 Laser Cleaning Machines

From my perspective, 3-in-1 laser cleaning machines are useful tools. They combine laser cleaning, welding, and cutting in one machine. This provides a complete answer for many industrial jobs. I find these machines work well and are very precise. They can do many different tasks in various industries.

Key Functions of 3-in-1 Laser Cleaning Machines

-

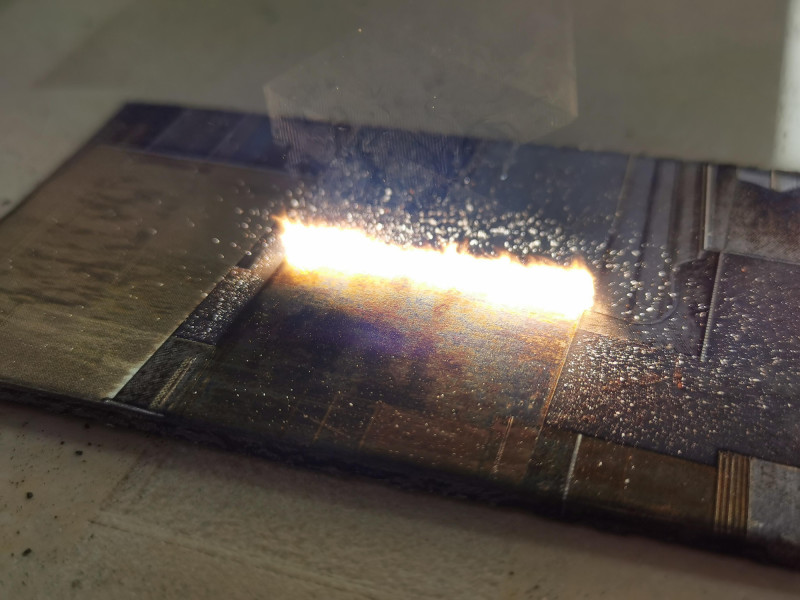

Laser Cleaning: – Removes rust, paint, and oxides from surfaces without contact, making it eco-friendly with minimal waste. Works well on metals like iron, stainless steel, aluminum, and also suitable for plastics and ceramics.

-

Laser Welding: – Delivers precise, clean welds on aluminum, steel, and titanium with minimal distortion. Great for joining different metals and supports spot, seam, and pulse welding modes.

-

Laser Cutting: – Offers high-precision cutting on thin metal sheets and small parts—ideal for jobs requiring accurate material shaping.

Practical Applications

These machines are widely used across industries like automotive, shipbuilding, aerospace, biomedical, and manufacturing. You’ll often see them in action cleaning rust off machinery and molds, welding intricate metal components, or cutting metal parts for repairs and construction. Whether it’s restoring precision tools or building high-performance parts, they play a key role in keeping operations running smoothly and efficiently.

Because these machines have many features and can handle different tasks, many industries choose them. I believe they are a dependable, all-in-one tool.

1. MaxWave 3-in-1 Fiber Laser Cleaning Machine

Key Features and Specifications

- Laser Power: It has a strong 1500W fiber laser. The wavelength is 1064-1090nm. I find this gives great results for many jobs.

- Adjustable Parameters: You can adjust the power from 10-100%. The laser frequency adjusts between 50-50000Hz. I like this control because it ensures accuracy for different tasks.

- Spot Adjustability: You can change the laser spot width from 0.2mm to 5mm. I think this flexibility is great for detailed work.

- Material Compatibility: It works well with many metals. This includes stainless steel (weld up to 8mm, cut up to 3mm), aluminum, copper, and titanium. I find this range very useful.

Design and Comfort Features

The handheld laser head weighs just 0.7kg, making it comfortable for extended use without fatigue. With 10m or 15m flexible fiber options, it offers great mobility during operation. The touchscreen interface is intuitive and provides precise control, while the air-cooled system keeps the machine lightweight, portable, and reliable even during long working sessions.

Pors and Cons

The MaxWave 3-in-1 Fiber Laser Cleaning Machine combines welding, cleaning, and cutting in one compact unit. It offers high versatility, easy operation, and efficient metal processing, though it may lack the power and specialization of single-function machines for heavy-duty tasks.

I recommend this machine for: – Making automotive parts – Producing advertising signs – Creating precision hardware and gifts – Working with stainless steel, carbon steel, aluminum, and other metal alloys.

2. iGCL-HC 3-in-1 Fiber Laser Cleaning Machine

I think the iGCL-HC 3-in-1 Fiber Laser Cleaning Machine is a very useful tool. It combines laser cleaning, cutting, and welding in one machine. We designed this versatile laser machine to be easy to carry and simple to operate. It performs very well. I find it works well for many factory jobs and outdoor tasks.

Key Features and Specifications

- Wavelength Range: It uses a 1070±20 nm wavelength. This helps it work very accurately.

- High-Power Options: You can choose from 1000W, 1500W, 2000W, or up to 3000W models. These power levels work fast for cleaning and cutting.

- Wide Spot Range: The welding spot size can be set from 0.5 to 5 mm. The cleaning spot size can be as large as 50 mm.

- Customizable Cable Length: You can get a cable up to 20 meters long. This is great for working outdoors or in large spaces.

Core Components

The water cooling system ensures stable performance even at high power. A pre-set parameter library speeds up setup with adjustable settings for different materials. The customizable fiber cable makes installation flexible for various factory environments.

Pors and Cons

The iGCL-HC 3-in-1 Fiber Laser Cleaning Machine is compact, versatile, and easy to use—ideal for welding, cleaning, and cutting. Its all-in-one design boosts efficiency, though single-function machines may perform slightly better for specialized tasks.

The iGCL-HC 3-in-1 Fiber Laser Machine offers advanced technology. It comes in a simple-to-use and portable package. I think it is a smart purchase for businesses that need a laser tool for many functions.

3. Riselaser RL-F1500 3-in-1 Fiber Laser Cleaning Machine

I think the Riselaser RL-F1500 is a useful and effective 3-in-1 fiber laser cleaning machine. It can weld, clean, and cut. This makes it a good selection for many industrial uses. Let me break down its main features, details, and how you might use it:

Technical Specifications

- Energy Use: Uses less than 6kW of electric power.

- Frequency: You can adjust it from 1-20Hz. You can also set custom pulse widths (0.1-20ms).

- Spot Size: Adjust the spot size between 0.1mm and 3.0mm for accurate results.

- Welding Gap Tolerance: It supports gaps up to 1.2mm or less.

- Fiber Details: It comes with a 25µm core and a standard 10m fiber cable. You can get a 15m cable for more flexibility if needed.

Key Features

This machine offers high precision with its 2-axis high-speed servo motor and comes in 1000W, 1500W, or 2000W options to suit different project needs. Its compact size (1000×600×800mm) fits well in various workspaces, and the water cooling system ensures stable performance during long operations.

Pors and Cons

The Riselaser RL-F1500 3-in-1 Fiber Laser Cleaning Machine offers versatile functionality with welding, cutting, and cleaning in one device. Its high power and user-friendly interface make it ideal for industrial use. However, due to its larger size and weight, it may be less convenient for highly mobile or confined workspace operations.

From my perspective, the Riselaser RL-F1500 is a strong choice for industries that require accuracy, steady performance, and flexible laser functions.

5. Acctek AKQH Series Laser Cleaning Machine

I find the Acctek AKQH Series notable because it combines laser cleaning, welding, and cutting in one machine. Based on my experience, its features and specifications make it a strong choice for many industrial uses.

Specifications and Models

- Laser Power Options: 1500W, 2000W, 3000W

- Central Wavelength: 1064 nm

- Power Range: You can adjust it from 1% to 100%

- Speed Range: 0-120 mm/s with ±0.01 mm repeat precision

- Welding Depth: 0.1 – 4 mm

- Cooling System: It uses an industrial thermostatic water tank for cooling.

Key Features

The 3-in-1 functionality of this machine—laser cleaning, welding, and cutting—is highly practical. Its compact, wheeled design makes it easy to move between work areas, adding flexibility. With intuitive controls and simple function switching, it requires minimal training. It’s well-suited for industries like automotive, aerospace, medical, metal fabrication, and electronics, handling even large and complex parts with ease.

Why Choose Acctek AKQH Series

I recommend the Acctek AKQH Series for businesses that need high precision and flexibility. It offers steady performance for many industrial jobs.

Pors and Cons

The Acctek AKQH Series Laser Cleaning Machine is praised for its high cleaning efficiency, non-contact process, and environmentally friendly performance, making it ideal for removing rust, paint, and oil without damaging the base material. However, it can be relatively expensive for small businesses, and requires trained operators to fully utilize its potential.

6. Maxcool MCW Series Laser Cleaning Machine

I find the Maxcool MCW Series 3-in-1 Laser Cleaning Machine is a flexible choice for professionals. It helps you work efficiently with welding, cutting, and cleaning. Here is some information about its features:

Models and Power Options

- The series includes three models: MCW-1500, MCW-2000, and MCW-3000.

- You can get power levels of 1500W, 2000W, or 3000W. It uses a fiber laser. For generators, you can choose Raycus, BWT, or Max.

- The power stability is ±5%. I think this ensures the machine works steadily.

Efficient Cooling System and Control Features

The machine features a water cooling system to prevent overheating and extend its lifespan. With intuitive controls, users can easily adjust settings for different tasks, making operation simple and efficient.

Pors and Cons

The Maxcool MCW Series Laser Cleaning Machine is compact, easy to use, and effective for removing rust, paint, and oil on various surfaces. Its portable design is great for on-site work, though it’s less efficient for large or heavily contaminated areas, making it best for small to medium-scale tasks.

I suggest this series for industries like automotive, aerospace, electronics, and metal fabrication. It offers excellent value and performs dependably for professionals.

6. Fortunelaser Handheld 3-in-1 Laser Cleaning Machine

Technical Specifications

- Laser Power Options: You can get it in 1000W, 1500W, or 2000W versions.

- Laser Wavelength: It uses a 1080nm wavelength. This helps it work better.

- Cooling System: It uses water cooling. This helps it perform well and consistently. I think water cooling is a reliable choice.

- Dimensions and Weight: It has a small structure measuring 100 x 68 x 45 cm. It weighs 165kg.

- Fiber Length: The standard fiber length is 10m. You can extend it to 15m if you need more reach.

Key Features

The machine’s all-in-one design integrates the laser, chiller, and controls into a compact, movable frame, saving space and improving convenience. It supports welding, cutting, and cleaning with a single laser head, making task switching easy. Built-in safety systems, including alarms and power cut-off, enhance operational safety. It also offers high compatibility with various fiber lasers and runs stably at up to 2000W.

Why I Recommend the Fortunelaser Handheld 3-in-1 Machine

This laser cleaning machine delivers fast, precise results on various materials. Its compact, lightweight design makes it easy to move and use in different workspaces. With adjustable spot sizes for welding (0–6mm) and cleaning (0–50mm), it adapts to different tasks. It also works with collaborative robots, improving efficiency and reducing fatigue.

Pors and Cons

The Fortunelaser Handheld 3-in-1 Laser Cleaning Machine is compact, easy to use, and supports cleaning, welding, and cutting in one device. It’s highly versatile, though less specialized than single-function machines and has a higher upfront cost.

In my opinion, the Fortunelaser Handheld 3-in-1 machine is a flexible, high-performing choice. I think it’s great for people working in manufacturing, industrial upkeep, and repair. It makes welding, cutting, and cleaning tasks simpler and more dependable.

Conclusion

Choosing the right 3-in-1 laser cleaning machine can transform your workflow—saving time, boosting precision, and cutting down costs. Whether you’re upgrading your workshop or starting a new business, investing in one of these top machines means you’re ready for any task: welding, cleaning, or cutting. Don’t wait—equip your team with the versatility and power to do it all. For more information or to get a quote, contact us now!

Recent Comments