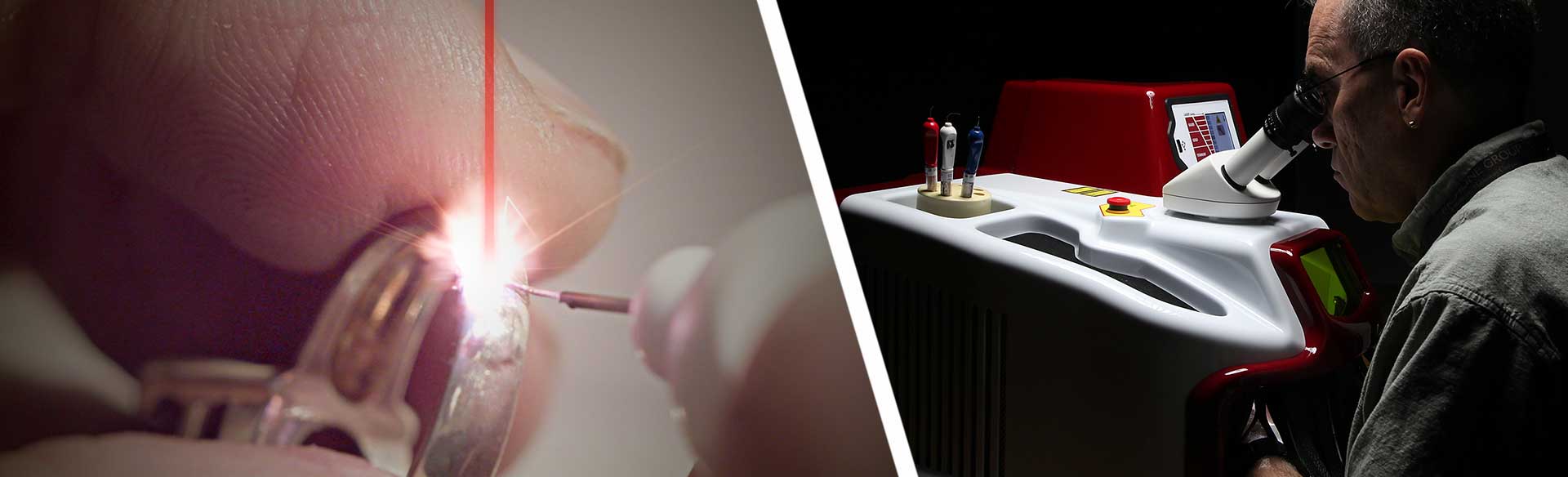

Say goodbye to the old torch-and-solder days—laser welders are changing the jewelry game. Whether you’re resizing a ring, repairing a chain, or restoring a delicate antique, these precision tools let you weld metal with pinpoint accuracy, minimal heat, and stunning results. Let’s explore why jewelers everywhere are making the switch.

What Is a Jewelry Laser Welder?

Let me explain what a jewelry laser welder is. It’s a specific type of machine used in jewelry making. It uses a focused, strong laser beam to join metal parts together. I find this technology allows jewelers to do very precise work. It welds the exact spot needed. This process limits heat exposure to the metal and gemstones nearby. From my perspective, this precision is crucial when you work with delicate materials or complicated jewelry pieces.

Key Features and Technology

- Precision Welding: The laser targets a tiny area (as small as 0.2mm) with wavelengths around 1064nm, allowing for delicate work like thin chains and intricate settings without damage.

- Adjustable Power and Spot Size: Jewelry laser welders range from 60W to 200W with pulse energies up to 11kW. Spot size (0.2–2.5mm) and pulse width (0.2–50ms) are adjustable to suit different tasks.

- Advanced Controls and Cooling: Most models feature touchscreen controls and microscope options (15× or 40×). Built-in air or water cooling ensures reliable performance.

- Non-Contact and Clean Process: The non-contact nature minimizes the risk of scratches or contamination, resulting in clean, nearly invisible welds with minimal oxidation or discoloration, saving time on cleaning.

Benefits of Using a Jewelry Laser Welder

Invisible, Strong Welds: I love how jewelry laser welder are nearly invisible, keeping the jewelry looking flawless. They’re also up to 260 times stronger than traditional solder joints and sometimes even stronger than the original metal.

Protects Sensitive Materials: The heated area is very small. I appreciate that this protects nearby metals and fragile gemstones, like pearls and opals, from heat damage or changing color.

Works with Multiple Materials: I find it great that these welders work on many materials. They can weld gold, silver, platinum, titanium, stainless steel, and various alloys. This makes them useful for working with both valuable and costume jewelry.

High Productivity: In my experience, laser welding works much faster than older methods – up to 10 times faster. It can operate continuously, which is helpful for busy jewelry shops.

Reduces Cleanup: I like that the focused process means less need for cleaning or finishing after welding.

Applications in Jewelry Making

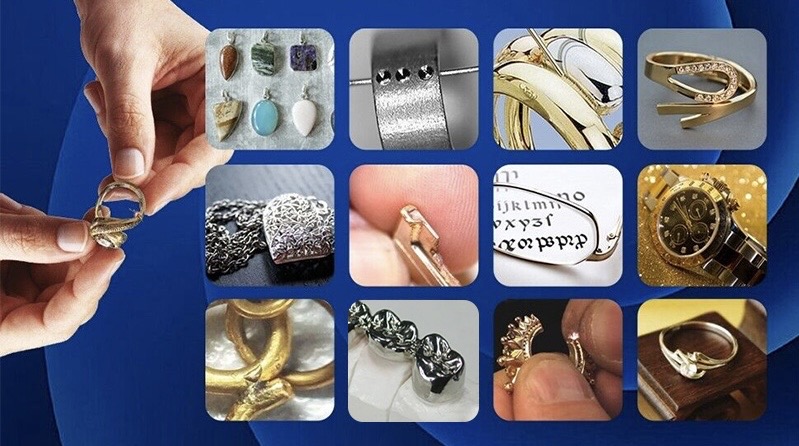

Here are some common uses I see for these welders: – Resizing rings – Re-tipping prongs and fixing bezel settings – Putting necklaces, bracelets, and earrings back together – Joining different metals smoothly – Repairing costume jewelry, glasses frames, and watch bands – Creating custom jewelry with detailed designs

How Does a Jewelry Laser Welder Work?

A jewelry laser welder directs a strong, focused light beam onto a tiny spot of metal. This beam creates intense heat. It melts and joins metal pieces very quickly. The outcome is an almost invisible, strong bond between the metals. We can control the welding process very precisely. This allows jewelers like me to work on small parts with little risk.

Key Working Principles and Steps

Laser welding works by precisely heating only the area we need, melting the metal at the focus point to form a tiny weld pool. As the laser pulses or moves, this pool quickly cools and solidifies, bonding the metals cleanly. You can fully control the beam size (0.2–2.5mm), power, and pulse duration (0.1–50ms), making it perfect for delicate or detailed work. Plus, shielding gases like argon or helium keep the weld clean by blocking air and contaminants—a must for high-quality results.

Technical and Operational Highlights

Modern jewelry laser welders pack a punch with peak power from 2kW to 11kW and average output between 60W and 200W. New models, like the iWeld 60W Benchtop, can even run 24/7 without breaking a sweat. Thanks to air or water cooling, overheating isn’t a problem—air cooling is a favorite for its low maintenance. With digital controls, you can instantly tweak pulse energy, frequency, and beam size. And with HD cameras, microscopes, and smart screens, keeping weld quality sharp and precise has never been easier.

Performance Data and Efficiency

Laser welding is up to 10 times faster than traditional soldering, which means more jobs done in less time. High-quality machines can last over 100,000 hours with minimal maintenance or supplies, keeping running costs low. Plus, the precise, focused heat protects nearby stones and delicate details—a huge win for fine jewelry work.

In my view, jewelry laser welders have really changed jewelry workshops today. They offer great efficiency, pinpoint accuracy, and flexibility. This is much better than older soldering ways.

Key Features of Jewelry Laser Welders

From my perspective, jewelry laser welders have advanced features that give great precision, flexibility, and safety for jewelry work. I find these features help jewelers do detailed work well and get the same results every time.

Great Precision & Micro-Welding

Focused laser energy makes it easy to weld tiny, delicate parts with precision—essential for fine jewelry work. With adjustable spot sizes from 0.05 mm to 2.5 mm, you can reach tight spaces and fragile areas with ease. It’s perfect for retipping prongs, repairing thin chains, and working on fine metal sheets without damage.

Small Heat-Affected Zone (HAZ)

The highly focused laser beam keeps heat exactly where it’s needed, protecting gems and nearby metal from damage—crucial when working with valuable pieces. It also reduces the risk of color changes, oxidation, and warping, making it ideal for heat-sensitive and high-end jewelry.

Clean, Smooth, Non-Contact Welding

Since laser welding is a non-contact process, it reduces physical stress on the piece and keeps dirt and debris out. The result? Smooth, clean welds with minimal marks—less time spent on polishing and finishing, and more time getting work done.

Works with Many Materials

Laser welders can handle gold, silver, platinum, titanium, alloys, and even mixed metals—making them incredibly versatile. In my experience, they’re perfect for everything from rings, bracelets, pendants, and watches to dentures and tiny electronics.

Adjustable Settings & Advanced Controls

Laser welders offer precise control over pulse energy, width, and frequency. Controls vary—touchscreens, joysticks, or switches are common. Some models, like the MaxWave MW-QW200, even auto-adjust settings by metal type and spot size, helping prevent overheating and streamline your workflow.

Better Viewing & Imaging

Built-in microscopes (10x–40x magnification) give you a clear, detailed view while welding. Paired with HD or CCD cameras and 360° shadow-free LED lighting, they make your work more accurate and comfortable—and I’ve found they really help reduce eye strain during long sessions.

Comfortable Design & Use

Work areas are roomy, with armrests and adjustable lights. Jewelry laser welder makes handling different jewelry sizes comfortable. The controls feel natural to use for long periods, which helps reduce tiredness.

Small & Adaptable Designs

Space-saving models range from compact desktop units (around 32kg) to modular systems (under 180kg). I appreciate that the modular design makes them easy to fit into any workshop, upgrade down the line, and minimize downtime during maintenance.

Maintenance & Long Life

Durable parts, such as ceramic condensing cavities, extend the machine’s lifespan. With maintenance plans and easy part replacements, the machine stays in top shape, while also making it easier to manage wear-and-tear parts.

Key Technical Specs and Examples

- Laser power: Often 40–300J. Models like the MaxWave MW-QW200 offer 200W continuous power, 2kW peak, a 0.1mm spot size, and can run 24 hours straight.

- Orotig Evo White: Offers 160J, 7kW peak power, a 0.15–1.5mm spot size, and smart automatic setting adjustments.

In my opinion, jewelry laser welders are vital tools for today’s jewelry workshops. They provide excellent accuracy, consistent results, and the flexibility needed for many different repair and creation tasks.

Applications of Jewelry Laser Welder

Jewelry laser welders aren’t just for fixing broken chains, rings, or prongs—they’re also widely used for welding dental frameworks, eyeglass frame joints, and repairing delicate watch components. With high precision and minimal heat impact, they’re ideal for working on small, fragile metal parts.

Common Laser Welding Applications in Jewelry

-

Jewelry Repair and Fabrication: Perfect for fixing broken chains, marking rings, earrings, and prongs. The welds are nearly invisible and preserve the original look.

-

Watch Repair: Used to weld tiny gears, watchbands, and cases with high precision and no damage to surrounding parts.

-

Eyeglass Frame Welding: Ideal for stainless steel and titanium frames—strong, precise welds that maintain the frame’s appearance.

-

Dental Prosthetics: Suitable for welding dental alloys in denture frameworks. Delicate welds reduce the need for post-processing.

Industry Impact and Market Data

The global laser welding market, including jewelry, is on the rise, expected to grow from USD 2.03 billion in 2022 to USD 2.79 billion by 2029—a 4.7% CAGR. The Asia-Pacific region is leading this boom, with North America and Europe also seeing rising demand as laser welding becomes more mainstream. Jewelers using laser welders report improved product quality, faster repairs, and higher profits. The investment pays off quickly, saving on labor and materials—making it a smart choice for any jeweler.

I believe jewelry laser welders are now vital tools in modern jewelry shops. They allow for accurate repairs and new designs. They make workflows efficient and work with many metals. They help with both standard jobs and difficult restorations. This makes them essential for making and repairing jewelry today.

What Jewelers Say

Many jewelers I know say their laser welder soon becomes a tool they can’t work without. They use it for chain repairs, fixing costume jewelry, and retipping prongs. I often hear feedback expressing surprise at its everyday performance, the strength of the welds, and how many tasks it can handle.

Summary

A jewelry laser welder isn’t just a tool—it’s your shortcut to cleaner welds, faster repairs, and happier clients. Whether you’re running a busy studio or just starting out, the right machine can transform your workflow and boost your profits. Don’t let old methods slow you down—invest in precision, power, and peace of mind today.

Recent Comments