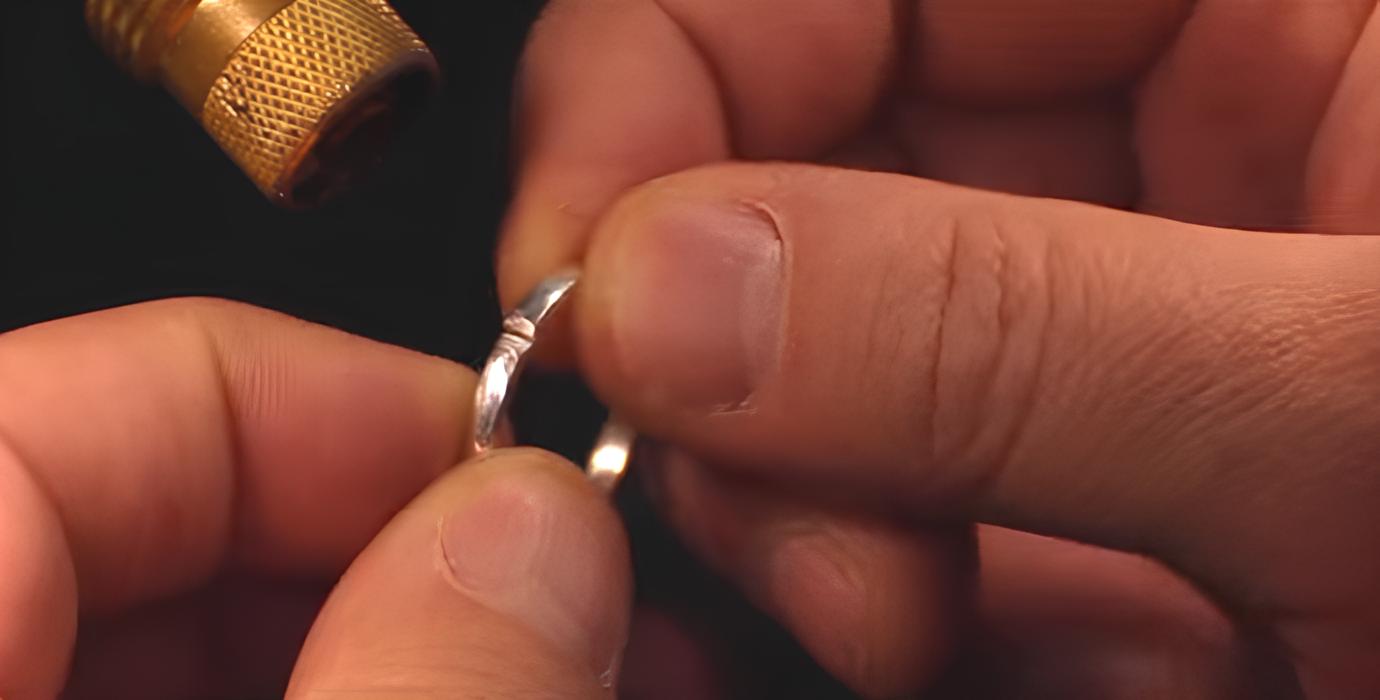

Have you ever found yourself struggling with repairing intricate jewelry, worried about damaging delicate stones or overheating the metal? I know I have. But let me tell you, the landscape of jewelry repair has changed dramatically. In 2025, jewelry laser welding machines are revolutionizing the way we handle repairs.

With pinpoint precision and minimal heat, these jewelry laser welding machines ensure that your precious pieces are treated with the utmost care. The result? Cleaner, stronger welds with less risk to your valuable jewelry. But the real breakthrough? It comes down to one surprising feature that makes all the difference in the world.

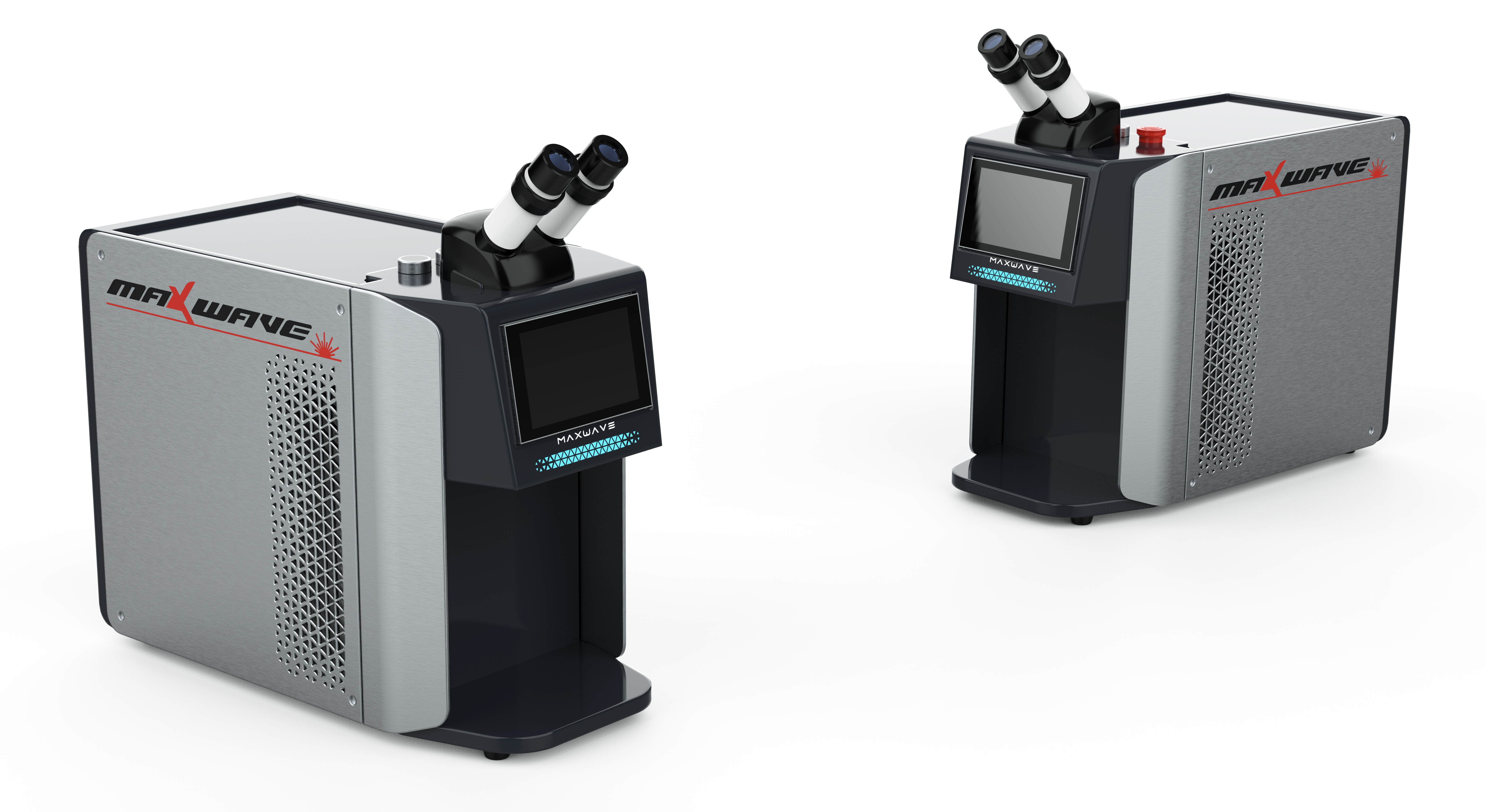

MaxWave QW Series Jewelry Laser Welding Machine

In my view, the MaxWave QW Series is a top choice for jewelry laser welding machines in 2025. Prices range from $3,700 to $4,900. The series includes the MW-QW60, MW-QW120, and MW-QW200 models. I recommend these machines for professional jewelry workshops. They are ideal if you need fast, precise welding for detailed and delicate designs.

Technical Specifications & Performance

- Output Power: You can choose 60W, 120W, or 200W models. The average output power is adjustable between 60–200W.

- Peak Power: It reaches up to 2000W peak power. This is great for spot welding and micro-welding tasks on gold, silver, platinum, and other precious metals.

- Pulse Width: You can adjust the pulse width from 0.2–15 ms. This gives you full control for different materials and thicknesses.

- Beam Quality (BPP): The beam quality is 1–2 mm × mrad. This helps make focused, clean, and dependable welds.

- Beam Diameter: The beam diameter goes down to 0.01 mm. I find this vital for detailed, expert-level welds on complex jewelry pieces.

- Cooling System: It uses an advanced air-cooled system. This allows you to work continuously without long waits for cooling.

- Weight & Size: It weighs about 32 kg and is compact. It fits well in busy workshop spaces.

- Machine Type: It’s a QCW (Quasi-Continuous Wave) fiber laser jewelry laser welding machine. This type means less heat damage nearby and quick pulses.

Productivity & Ease of Use

In my experience, jewelry laser weldig machine significantly increase speed, performing repairs up to 10 times faster than traditional soldering, which greatly boosts efficiency. They also require fewer consumables and less maintenance, reducing overall running costs. The machines are easy to operate, with intuitive controls—some advanced models even include touch screens and camera assistance, which I find very helpful. Additionally, you can adjust the spot position and intensity, allowing for precise calibration tailored to different types of jewelry.

Competitive Advantages

Jewelry laser welding machines are built for continuous operation with efficient air cooling and offer an impressive lifetime of over 100,000 hours. They provide flexible power and pulse settings, making them suitable for a wide range of jewelry repair and creation needs. With minimal maintenance and low consumable costs, they’re highly economical. Their compact yet durable design makes them an ideal choice for professional jewelry shops.

I think the MaxWave MW-QW series jewelry laser welding machine is excellent for jewelers. The MW-QW200 model is a great choice if you need an advanced laser welding machine. These machines give consistent, high-quality, and reliable results for production work and intricate jewelry tasks.

WTTTOOLS Jewelry Laser Welder 150W

In my opinion, the WTTTOOLS Jewelry Laser Welder 150W is a great choice for making and fixing jewelry professionally in 2025. It has a strong laser (150W max power, up to 40J energy). Based on my experience, this gives great results for tough jobs. The 1064nm laser wavelength works well with many precious metals. I find it compatible with gold, silver, platinum, and titanium.

Key Features and Technical Specifications

- Precision Welding: You can adjust the spot size from 0.2mm to 2mm. I think this is perfect for tiny welds and careful jewelry fixes.

- Adjustable Pulse Width: The pulse width goes from 0.1ms to 15ms. This gives you precise control for various welding tasks.

- Laser Frequency: You can set the frequency between 0–50Hz. I find this useful for both quick work and detailed repairs.

- Welding Depth: It welds from 0.1mm to 2.5mm deep. This works well for spot welds, general repairs, and resizing rings.

- Voltage Requirement: It needs standard 220V power (single-phase). Most jewelry shops should have this setup.

- Air Cooling System: The air cooling manages heat well and needs little upkeep. I recommend it for regular use.

- Integrated Microscope: It includes a strong microscope. This helps you line up and control work on small, detailed items precisely.

- Multi-Material Compatibility: Based on my experience, it works with many metals like gold, silver, platinum, titanium, steel, and bronze.

Accessories and Add-Ons

An optional built-in water cooling system is available, which jewelry laser welding machine I recommend if you plan to use the welder frequently. The machine features a touch screen for easy adjustment of settings. It also includes safety glass and an enclosed area to ensure user safety.

Price Range and Industry Feedback

The typical price for a jewelry laser welding machines ranges from $5,099 to $6,399, depending on the brand and setup. It’s widely praised for its efficiency and reliability, making it a favorite among both repair shops and small manufacturers. Users often highlight the low-maintenance air cooling, durable construction, and how well it performs with various precious metals.

ACCTEK 4-in-1 Laser Welder Machine 3000W Review

I think the ACCTEK 4-in-1 jewelry laser welding machine 3000W is a leading choice for jewelry laser welding in 2025. It provides high precision for detailed jewelry making. I find its combination of power, safety, and flexible use very appealing.

Core Technical Specifications

- Laser Power Options: 3000W (also available in 1000W, 1500W, 2000W)

- Laser Type: Continuous Wave Fiber Laser (Raycus, MAX, BWT source)

- Wavelength Choices: 1064nm, 1070nm, or 1080nm

- Power Adjustment: 1%–100%

- Working Modes: Continuous or modulation/pulse

- Maximum Welding Depth: Up to 4mm

- Repeat Precision: ±0.01mm (ideal for fine jewelry repairs)

- Line Length: Standard 10m (up to 20m)

- Cooling System: Industrial thermostatic water tank

- Max Air Pressure: 15 Bar

- Voltage: 380V

- Wire Feed Speed (AKH-3000): 15–600 cm/min

Key Features & Advantages for Jewelry Laser Welding

This jewelry laser welding machine combines welding, cleaning, cutting, and wire feeding in one machine—great for most jewelry workshop needs. It’s portable and easy to use, with a lightweight 0.7kg welding gun that reduces fatigue. Preset switching is quick, including wobble welding for wider seams. The double wire feeder (AKH-3000) adds speed and flexibility. However, the machine is quite large, so it needs enough workspace.

My Opinion: In my opinion, the ACCTEK 4-in-1 jewelry laser welding machine is a great fit for jewelry workshops and professional metalworking studios. Based on my review of its powerful laser, fast operation, safety features, and adaptable controls, I rank it as a top choice for jewelry laser welding in 2025.

WTTTOOLS Laser Welding Machine 1200W

Based on my experience, I think the WTTTOOLS jewelry laser welding machine is a top choice for jewelers who need precision and reliability in 2025. I like its mix of power and portability. Its features are easy to use. I find it great for repairs and making jewelry.

Key Technical Specifications

- Output Power: 1200W with a 220V input voltage

- Rated Power Consumption: 4kW (some models: 6kW)

- Fiber Cable Length: 5 meters

- Net Weight: 32–70kg (varies by configuration)

- Dimensions: 620 x 353 x 518.5 mm (excluding handle)

- Cooling Method: Air-cooled internal circulation

- Beam Quality: M2 <1.3 @ 20μm for precise, clean welds

- Fiber Core Diameter: 50μm (options: 20/25/100μm)

- Power Adjustment Range: 10–100% for task flexibility

- Center Wavelength: 1080nm (±10nm)

- Max Modulation Frequency: 20kHz

- Gross Volume: Under 0.1m³

- Operating Temperature Range: 5–40°C

Specialized Features for Jewelry Welding

The jewelry laser welding machine features an Auto Wire Feeder, ensuring smooth and continuous welding on various metals. The Class 2 Fiber Laser Gun provides good safety for handheld use, while the Red Light Pointer helps with accuracy and alignment. It also offers Continuous and Modulated Operation Modes, making it suitable for both detailed jewelry work and larger metal tasks.

Summary

The jewelry industry is evolving quickly, and jewelry laser welding machines are leading the way. Brands like MaxWave and ACCTEK offer unique benefits, so it’s important to choose the right one for your workshop. Technology keeps improving, and I’m excited about the potential these tools have to transform traditional jewelry making. They allow for incredible detail, are efficient, and help reduce environmental impact. With their balance of accuracy, power, and ease of use, these machines are a great investment for any serious jeweler looking ahead. For more details about jewelry laser welding machine or to get a quote, contact us today!

Recent Comments