Ever wonder how your favorite jewelry can look flawless and unique at the same time? From my perspective, laser technology in jewelry is doing amazing things now. It goes beyond just making strong bonds or creating fancy patterns. I think it changes how pieces are made and personalized. Lasers can make invisible repairs. They also add those special, personal details. Based on my observation, a lot happens with lasers that isn’t immediately obvious. But I find one key difference often gets overlooked. This happens when people compare laser welding and engraving.

My Take: Laser Welding and Laser Engraving Machine in Jewelry

In my view, laser welding and laser engraving are key tools for making and personalizing modern jewelry. Both use accurate lasers. However, they do different jobs and give different results for jewelers and customers.

Laser Welding: Strong Joins and Fixes

I find jewelry laser welder great for joining and fixing metal jewelry parts. It offers amazing strength and accuracy. This method uses a focused laser beam. This beam melts and joins metals like gold, platinum, silver, stainless steel, and titanium. The joints are almost invisible. They can be up to 95% as strong as the original metal. Sometimes, these laser-welded connections are 260 times stronger than soldered ones. Based on my experience, this makes it perfect for jewelry that takes a lot of wear, like rings and watchbands.

Here are benefits I see: – Very small heat zones. This protects the nearby material from damage, color change, or getting weaker. – Smooth joints without gaps or visible color changes. – You can join different types of metals. This allows for cool custom designs and tricky repairs.

I often use laser welding to fix broken ring parts, rebuild settings for stones, make gem settings stronger, and join different metals in special items. It also lets me make detailed changes without harming the jewelry’s original look or structure.

Laser Engraving: Adding Personal Touches and Art

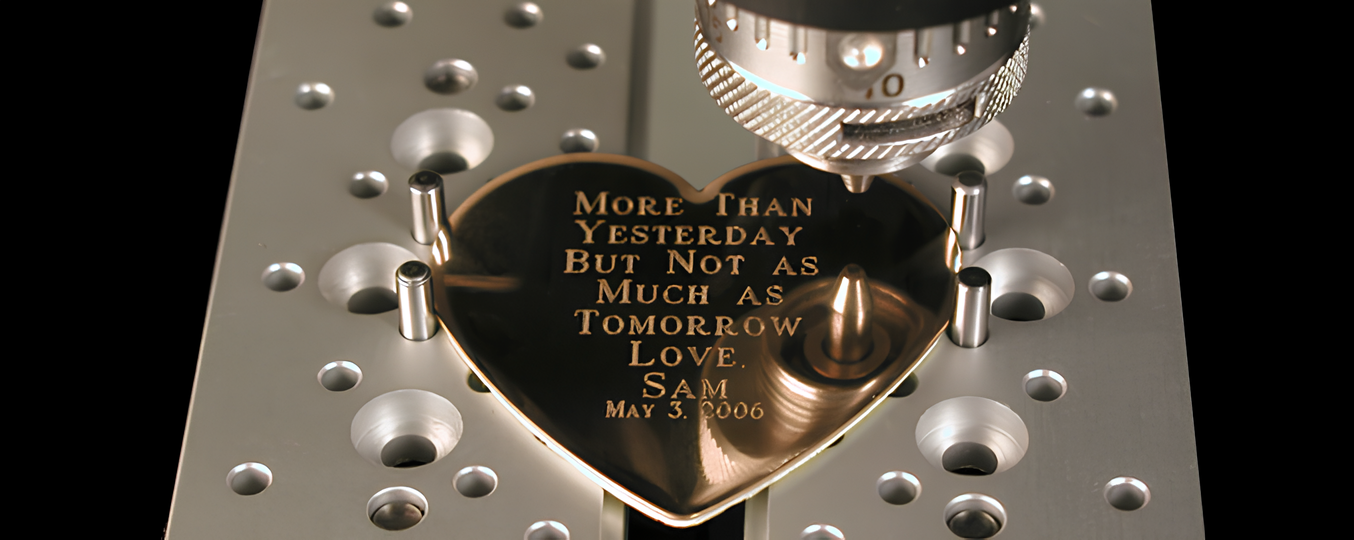

Laser engraving is different. I use it mainly for decorating surfaces and adding personal touches. This method uses a focused laser. It carves patterns, textures, logos, or text right onto metal, gems, or other good materials. It doesn’t change the item’s structure. Based on my experience, this makes it a good choice for adding details like initials, dates, or fancy designs.

Advantages I recommend: – Very fine details for special art and branding. – It doesn’t change the structure. This is perfect for delicate surfaces or thin jewelry pieces. – You can use it in many ways. From simple messages to detailed patterns.

People often use engraving for things like adding a wedding date inside a ring, carving fancy designs on pendants, or putting a name or message on a watch back.

How They Compare, In My Opinion

Laser welding: I use this for joining and repairs. It keeps the design’s look and allows for creative changes. It has little effect on nearby materials.

Laser engraving: This adds decoration to the surface. It creates exact, lasting personal touches. I think it makes each piece look more unique.

Both techniques add strength, value, and a personal touch to fine jewelry. In my opinion, they help jewelers like me create unique designs and meet customer requests for custom items today.

Process Description: How Laser Welding and Laser Engraving Work in Jewelry

Laser Welding Process in Jewelry

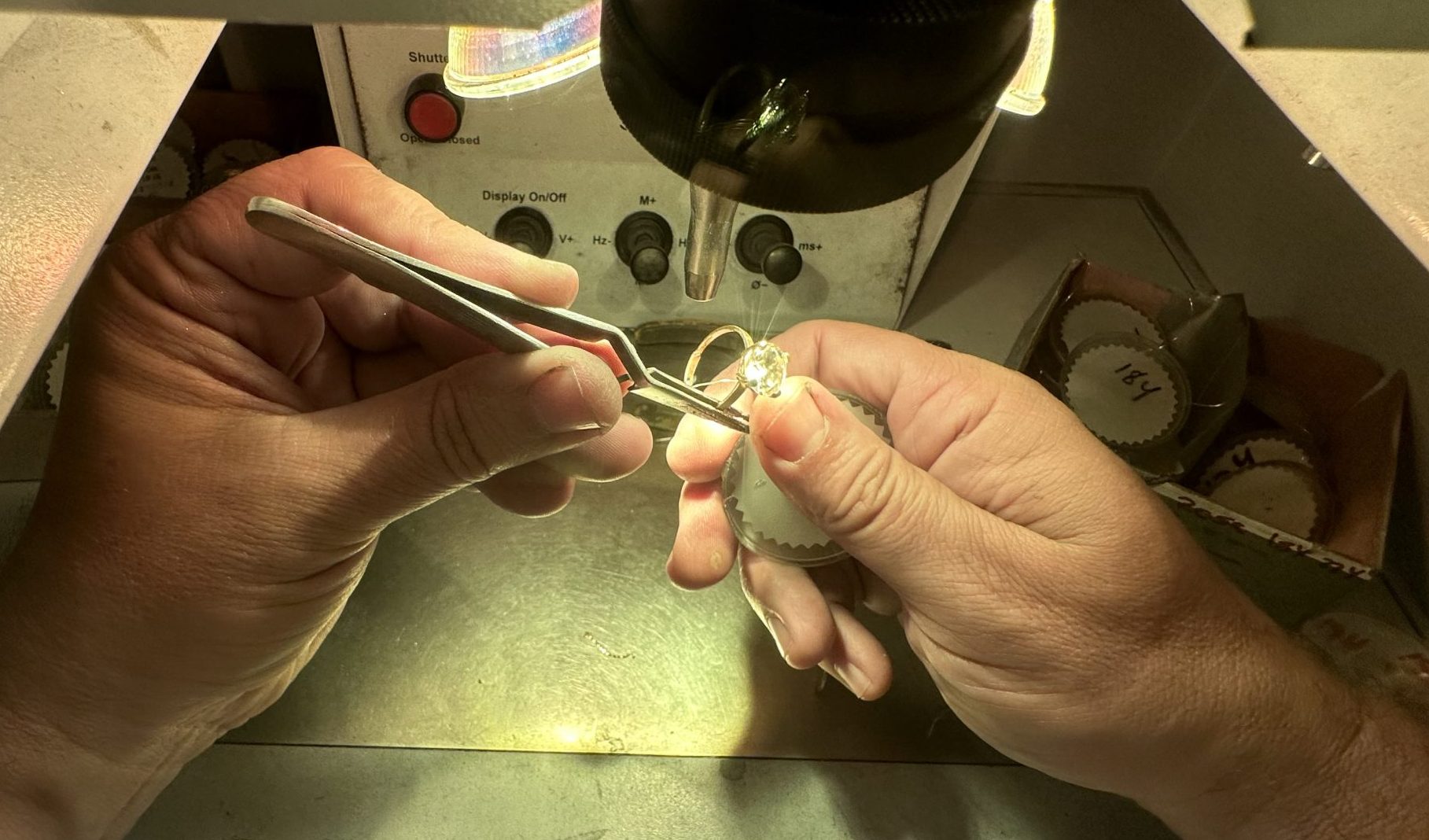

For laser welding, I find using a focused laser beam with jewelry laser welder is key to joining metals. Here’s how I see the process:

Alignment: First, the jeweler places the piece under the laser. They line up the spot that needs fixing or joining. From my experience, modern laser welders can target areas smaller than 0.1 mm. This is great for detailed jewelry work.

Starting the Pulse: Next, the jeweler presses a button. The machine then shoots a quick, strong laser pulse at the target spot. I’ve seen these pulses last only milliseconds.

Heating the Spot: This laser energy melts a tiny spot, joining the metal pieces. The heat affects just that small area. Based on what I know, this keeps nearby stones or decorations safe.

Controlling Settings: I suggest adjusting settings like pulse width, power, and repetition rate. This helps match different metals and the type of repair needed.

No Touching: Tools never touch the jewelry during this process. I like this because it prevents scratches or marks.

Speed and Finish: Repairs often take just seconds or minutes. I notice most welds look good right away and might need a quick polish, if anything.

Example: Let’s say I need to fix a ring prong. Using a 0.2 mm weld spot and laser energy between 5–50 Joules, the job often takes less than five minutes. In my opinion, that’s much quicker than soldering.

Laser Engraving Process in Jewelry

Now, let’s look at laser engraving. I see it as using a laser to turn surface material into vapor. This creates crisp, lasting marks. Here’s my take on the steps:

Setup: First, the jeweler places the jewelry firmly in the machine. Then, they use software to line up the engraving design very accurately.

Applying the Beam: Software controls the laser. For gold or silver, I often see power levels of 10–60 W. The laser moves over the design lines.

Removing Material: The laser removes a very thin layer of metal, about 0.01–0.2 mm deep. This action forms clear text, pictures, or logos.

Detailed Work: You can engrave tiny details even on small items like thin ring bands. Think serial numbers, initials, or complex micro-patterns.

No Contact Here Too: Like welding, no tools touch the jewelry. I appreciate that this means no physical stress on the piece.

Quick Work: Engraving is fast, with speeds from 200 to 2000 mm/s. Based on my experience, custom designs or numbers appear in just seconds.

Example: Engraving a tiny 1 mm-high serial number on a ring? I estimate it takes about three to ten seconds. It only removes about 0.02 mm of gold.

Applications in Jewelry: Practical Uses of Laser Welding and Laser Engraving

Laser technology changed how jewelers create, fix, and personalize fine jewelry. From my experience, understanding laser welding and laser engraving helps greatly. Let’s explore how jewelers use these tools day-to-day. I’ll show clear differences with examples and numbers.

Laser Welding Applications in Jewelry

Jewelry laser welder offers high precision. I find it essential for making and repairing jewelry. Here are some frequent uses:

Repairing Broken Chains and Components: Jewelers can fix damaged chains or reattach clasps fast. The heat zone is tiny, so gemstones usually stay put. This makes repairs much simpler, in my view.

Resizing Rings and Bracelets: Lasers put energy right where it’s needed. This protects fine designs. It also stops patterns or delicate settings from warping. You can achieve a clean finish.

Repairing Prong and Bezel Settings: Laser welding reinforces or rebuilds settings, mainly with platinum, gold, or silver. The gemstone stays safe. The jewelry’s look isn’t harmed. I think this is especially useful for securing valuable stones.

Filling Porosity and Defects: Jewelers use lasers to fix small manufacturing flaws. I believe this helps ensure pieces meet high quality standards. It also boosts customer happiness.

Assembling Intricate and Tiny Parts: Fine filigree and small chain links get joined with seams you can barely see. This gives more creative freedom for delicate or fragile designs compared to old soldering methods.

Creating Custom and Multi-Metal Pieces: Laser welding joins different metals. This opens doors for new mixed-metal jewelry styles. Joints become strong like molecules bonded together. Design options expand too.

Restoring Vintage Jewelry: Saving the original look and structure is key for old pieces. Laser welding provides gentle restoration. This makes it vital for antique repairs, in my opinion.

Case Data & Industry Impact:

- Laser welders often cut jewelry repair time by 50%. This is true for jobs where gemstones don’t need removal.

- The heat zone is usually under 1mm. This means low risk to nearby materials and stones. Based on my experience, this is a major advantage.

- Machines generally use 20W–150W lasers. This power range handles tiny welds for fine work and strong joins for bigger items.

- I’ve seen shops using laser welding have up to 60% fewer returns or reworks. This makes their business more profitable and dependable.

Laser Engraving Applications in Jewelry

Laser engraving serves both looks and function in jewelry. Common uses I see include:

Personalizing Jewelry: Adding names, dates, initials, or custom messages is easy and quick. I think this makes it great for gifts and special orders. It provides a personal touch customers often appreciate.

Etching Patterns and Images: You can engrave detailed patterns, textures, and even photo-like pictures. These go on rings, pendants, bracelets, and watch backs. This adds decorative appeal and helps brands stand out.

Marking for Identification: Engraving serial numbers, maker marks, logos, or metal details provides proof of origin. It also protects against fakes. I find this important for jewelers and customers, ensuring authenticity.

Key Comparison: Application Summary

Laser welding: Focuses on structure. It joins, repairs, resizes, assembles, fixes flaws, and mixes metals. I consider it the structural tool.

Laser engraving: Used for adding personal touches, designs, branding, and identification marks. I see it as the personalization and finishing tool.

To wrap up: I recommend laser welding for building, fixing, and ensuring jewelry lasts. Laser engraving makes pieces unique with decoration, personal touches, and ID marks. Both add significant value for jewelers and their customers.

Summary

I think laser technology effectively combines traditional jewelry skills with modern accuracy. Based on my experience, these lasers have opened up new possibilities for repairs and creating custom pieces. I expect these methods will improve even more down the road. This improvement will help make jewelry more unique, stronger, and more significant for the people wearing it. In the end, whether we use welding or engraving, the aim is always to safeguard and enhance the jewelry that represents life’s important memories. For more details about jewelry laser welder or to get a quote, contact us today!

Recent Comments