Have you thought about your shielding gas for jewelry laser welder? I believe the gas you pick affects your craft. It also impacts the environment. Choosing between argon and nitrogen makes a difference. In my experience, this choice changes more than just the weld’s strength or how it looks. Making the right selection can save you money. It also leads to cleaner air. Plus, you create fewer harmful waste products. But I find there’s a surprising point. Most people seem to overlook this factor when they consider their environmental effect…

Argon Vs. Nitrogen in Jewelry Laser Welder Review

Argon offers broader metal compatibility and deeper penetration, while nitrogen is more cost-effective and excellent for oxidation prevention when used with a jewelry laser welder in specific applications like jewelry.

| Property | Argon | Nitrogen |

|---|---|---|

| Inertness | Very inert, does not react | Some reactivity (nitrides form) |

| Cost | Moderate | Lowest |

| Weld Aesthetics | Bright, clean, white | Possible discoloration |

| Risk of Brittleness | Very low | High (with titanium, stainless) |

| Recommended Metals | Gold, silver, copper, titanium, platinum | Carbon steel, some stainless |

| Jewelry Suitability | Excellent | Limited |

| Potential Issues | None significant | Brittleness, porosity, poor color |

Argon in Jewelry Laser Welder

I find argon is a popular shielding gas for jewelry laser welder. It doesn’t react with other elements, it won’t catch fire, and it isn’t toxic. Its main job is to shield the weld spot from air contaminants like oxygen and nitrogen. This shielding is very important. I see this especially when working with metals that oxidize easily, such as aluminum, magnesium, and some alloys.

Benefits I See When Using Argon Gas for Jewelry Welding

- Contamination-Free Welding: Argon pushes air away from the weld zone. This prevents oxygen and nitrogen from causing oxidation or changing the metal’s color. Based on my experience, this gives you clean, strong welds that look much better.

- Arc Stabilization and Spatter Reduction: I find argon helps make the weld arc steady and reduces spatter. This gives you better control over the melted metal pool. This precise control is essential for tasks like fillet and butt welds, which I frequently do in jewelry work.

- Enhanced Safety Profile: Argon is safe because it won’t burn and isn’t poisonous. You must ensure good airflow in closed-off areas. Argon pushes oxygen out of the workspace, creating a risk of suffocation if you don’t have proper ventilation.

- Versatility Across Metals: I use argon to weld many metals, including gold, silver, platinum, palladium, titanium, copper, and stainless steel. It works well for jewelry parts up to about 1–1.3 mm in diameter.

- Material-Specific Performance: Argon provides great benefits for nickel white gold alloys. When used with a jewelry laser welder, I have seen it clearly improve welding results for these metals. But, you might not always need it. Platinum and higher-karat yellow golds can sometimes be welded well without argon. This depends on your skill and the specific alloy you are using.

Research Data and Mechanical Effects

Tensile strength and mechanical impact during laser welding have been studied in dental Co-Cr and Ni-Cr alloys. Research shows that using argon does not significantly change the weld’s tensile strength. The strength is more influenced by the type of metal being welded than by the shielding gas. This suggests that for a permanent jewelry welder, argon’s main benefit lies in improving surface quality and preventing contamination, rather than enhancing the physical strength of the weld across all metals.

Application Examples in Jewelry Work

- Titanium Welding: When welding pure titanium with a jewelry laser welder, I recommend always using an argon or similar inert gas shield. This prevents the metal from becoming brittle and stops surface oxidation. Different titanium alloys might have varying needs, so choosing argon is often a reliable approach for many situations.

- Machine Compatibility: I suggest using jewelry laser welders equipped with argon shielding. These machines are excellent for precise welding of metals in the 1–1.3 mm size range. Common tasks I use them for include chain repairs, prong re-tipping, and joining small components where a top-quality weld is critical.

Summary: Argon’s Features in Jewelry Laser Welding (My Perspective)

Argon provides an inert shielding environment that doesn’t react with the metal, helping to prevent oxidation, color changes, and contamination during laser welding. When using a jewelry laser welder, it enhances the appearance of welds and keeps surfaces clean, which I find especially important when working with challenging alloys like nickel white gold and titanium. While its impact on weld strength depends on the specific alloy—some metals may not become physically stronger—the surface quality consistently improves in my experience. It’s also important to maintain proper ventilation in the workspace to ensure safety when using argon.

Nitrogen in Jewelry Laser Welder

I find nitrogen is a frequent choice for a shielding gas in jewelry laser welder. Its main purpose is to shield the weld area from air, particularly oxygen. This shield stops oxidation, which is like rust, and helps me achieve better quality welds.

Why I Suggest Using Nitrogen as a Shielding Gas

- Saves Money: Nitrogen costs less and is easy to get. Based on my experience, this makes it a practical selection for welding mild steels and for jewelry work where budget matters.

- High Purity Option: Some machines have built-in N₂ generators. These can supply 99.99% pure nitrogen. I believe this high purity helps ensure clear welds and strong protection.

- Precise and Clean Welds: Using nitrogen shielding helps me make very precise welds. The heat affects only a small area around the weld. This means the finished seams need less cleanup work later. They also have fewer flaws you can see, which I know is important for detailed jewelry.

- Protects Your Welder: Nitrogen also helps keep the welding machine’s sensitive parts safe. For example, it protects the focusing lens. It does this by cutting down on spatter and stopping vapor from building up.

- Works for Many Jewelry Tasks: We use nitrogen in handheld laser welders and fiber laser welders. It helps create strong joins on the kinds of metals often used in making jewelry.

Key Jobs and Where We Use It

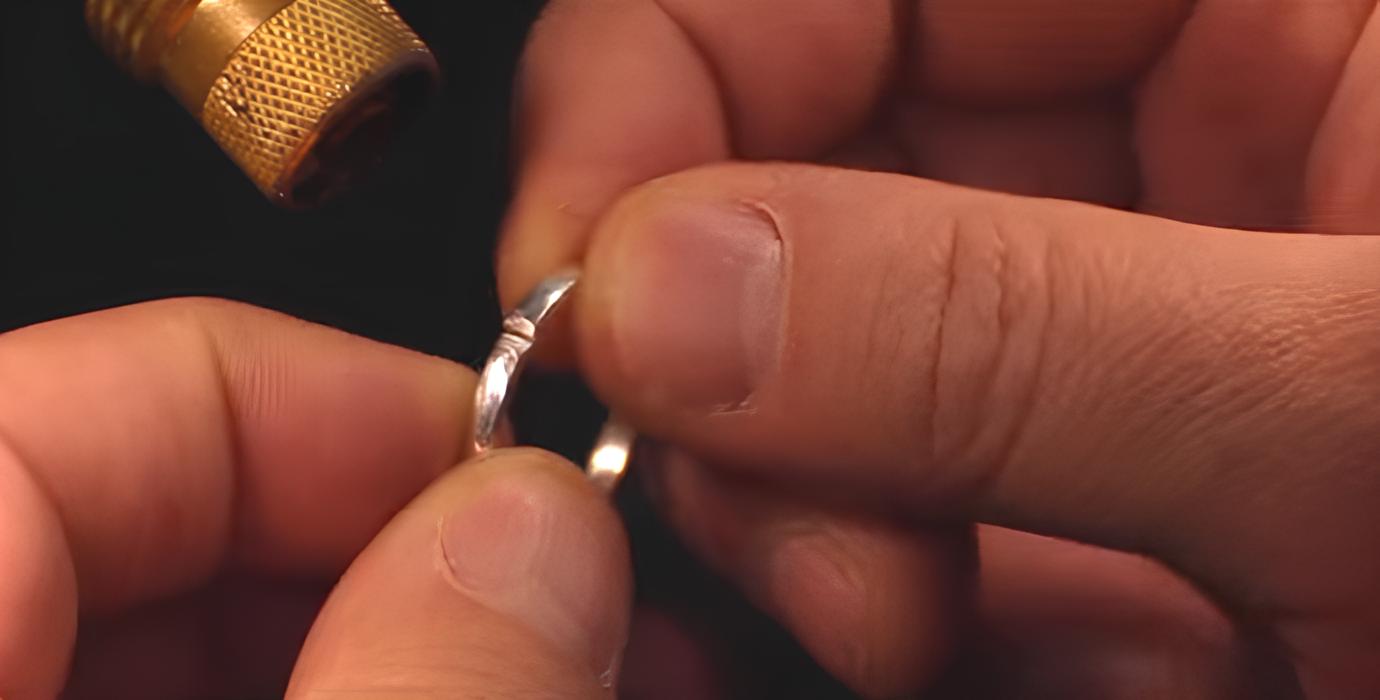

Using nitrogen during welding offers several key advantages. When used with a jewelry laser welder, it effectively shields the weld spot, keeping air out and preventing oxidation and porosity. Additionally, it protects the machine’s optics from spatter and smoke, extending equipment lifespan. Nitrogen is especially beneficial for jewelry repairs, including fixing and re-tipping prongs on rings and bracelets, welding seams on chains and frames made of precious metals, and spot welding costume jewelry parts where a clean, oxidation-free join is essential.

Using nitrogen during welding offers several key advantages. It effectively shields the weld spot, keeping air out and preventing oxidation and porosity. Additionally, it protects the machine’s optics from spatter and smoke, extending equipment lifespan. Nitrogen is especially beneficial for jewelry laser welders and jewelry repairs, including fixing and re-tipping prongs on rings and bracelets, welding seams on chains and frames made of precious metals, and spot welding costume jewelry parts where a clean, oxidation-free join is essential.

Things to Keep in Mind

Risk of Making Metal Brittle: Be aware that nitrogen can make some metal types brittle. I find it works best for mild steel and certain silver and gold types. It might not be the best choice for titanium or steels with a lot of chromium.

Comparing with Argon: Nitrogen shields well for most jewelry tasks I do. Sometimes, though, I might prefer argon. This is usually when working with precious metals where I need absolute purity or must avoid making the metal brittle at all costs.

Why Choose Nitrogen for Laser Welding Jewelry?

Many people choose nitrogen for welding because it’s cost-effective and highly effective at preventing oxidation. In my experience, using nitrogen with a jewelry laser welder helps create clean, strong welds with an attractive finish, which is especially important for jewelry. Advanced jewelry laser welders often come with built-in nitrogen generators, making it even more convenient. While nitrogen works especially well for mild steel and certain precious metals, it’s important to note that it may not be suitable for all metal types.

To sum up, using nitrogen shielding helps create strong, good-looking welds. It also means less cleanup after welding. For these reasons, I think it’s a sensible and popular option for most jewelry making and repair jobs.

Summary

I’ve looked into using argon and nitrogen as shielding gases for my jewelry laser welder. Based on my experience, I learned a lot. From what I’ve seen, each gas has its own benefits. The best choice depends on the type of metal I’m welding and the final look I want. I find argon works best with metals that react easily. It also gives a much nicer finish, in my opinion. Nitrogen is a good option if I need to save money, and it works well for many jobs.

Knowing the right gas for the job helps me get better results. I can make stronger welds and use methods that are kinder to the environment. This helps me create jewelry that looks great and is made with care. For more details about jewelry laser welding machine or to get a quote, contact us today!

Recent Comments