Tired of rust, paint, or grease ruining your workflow? You’re not alone. Whether you’re in manufacturing, automotive, or restoration, the demand for fast, eco-friendly, and precise cleaning solutions is growing—and laser cleaning machines are leading the charge.

But with so many options flooding the market, how do you cut through the noise and find a machine that’s actually reliable, durable, and worth your investment? In this guide, we’ll walk you through the key factors that separate top-tier machines from the rest—so you can choose with confidence and power up your productivity.

Laser Cleaning Machine Specification

Picking the right power for your laser cleaning machine matters a lot. It helps you clean well and keeps surfaces safe. Here’s what I think you need to know:

Applications and Power Needs

- Rust Removal: You’ll need CW lasers between 1000W and 2000W for quick, good cleaning.

- Paint Removal: Use 100W to 2000W to balance speed and surface protection.

- Mold Cleaning: Based on how dirty it is, you need 50W to 1500W.

- Thin Surface Dirt Removal: I recommend pulsed systems with 50W–300W to protect delicate surfaces in precision work.

Power Input and Use

- Input voltage needs:

- AC 110V-220V for small laser systems.

- AC 380V±7% for big units.

- Power use:

- Pulsed lasers need just 1.5kW.

- Big CW systems use up to 13kW.

Cleaning Speed and Results

- A 1500W CW fiber laser cleans up to 50m²/hour – more power means faster work.

- Larger 3000W output systems work very well for big cleaning jobs and save time.

Cooling Needs

- Air Cooling: Works for systems up to 500W, mostly for low-power jobs.

- Water Cooling: Needed for medium and high-power lasers (1000W–3000W) to keep them cool and working well.

Safety and Green Concerns

- Pulsed Lasers: Give exact cleaning with less heat damage, but cost more.

- CW Lasers: Cost less for big jobs but need good heat control to avoid damage.

From my experience, knowing these power details helps you make smart choices. You can match the laser to your exact needs for best results and surface care.

Laser Cleaning Machine Types

To pick the right laser cleaning machine, I find it’s important to know what types are available. They differ in delivery systems, beam modes, power, and what materials they work with. Here’s my breakdown:

Based on Delivery System

Handheld Laser Cleaners

These portable laser cleaning machine are easy to move and perfect for flexible projects—especially when dealing with odd-shaped surfaces or tight spaces. I often recommend them for small jobs like rust removal in hard-to-reach areas. Just keep in mind, their open-beam design means strict safety precautions are a must during use.

Hand-Loaded Workstations

These laser cleaners are designed for use in safe, controlled environments, making them a solid choice for medium-sized tasks. In my experience, they’re especially effective for jobs like cleaning molds or production parts—offering strong performance without sacrificing safety or precision.

Conveyor Laser Cleaning Machines

These systems integrate seamlessly with conveyor belts, enabling continuous, hands-free cleaning. They’re ideal for high-speed, non-stop operations—like in car manufacturing plants—where efficiency and consistency are everything.

Robot Laser Cleaning Machines

These systems pair with robotic arms to deliver pinpoint cleaning on intricate surfaces. They’re a go-to solution in the aerospace and automotive industries, where precision and automation are key to handling complex cleaning tasks.

OEM Laser Cleaning Systems

These systems can be tailor-made to fit unique factory production lines, offering seamless integration and optimized cleaning for highly specific industrial needs.

Comparison Table

| Machine Type | Precision Level | Cleaning Speed | Mobility | Applications |

|---|---|---|---|---|

| Handheld Laser Cleaner | Medium | Medium | High | Rust, paint cleaning on complex, movable equipment |

| Hand-Operated Workstation | High | Medium | Medium | Mold cleaning, industrial part cleaning |

| Conveyor Laser System | Low | High | Low | Continuous production line cleaning |

| Robot-Mounted Cleaner | High | High | Low | Aerospace, automotive precision cleaning |

| Pulsed Laser | Very High | Moderate | Medium to High | Rust removal, cleaning delicate artifacts |

| Continuous Wave Laser | Low | Very High | Low to Medium | Heavy-duty industrial tasks, thick rust removal |

I suggest you look at your specific cleaning needs – what material you’re cleaning, how precise you need to be, and the size of your job – to pick the best laser cleaning machine for you.

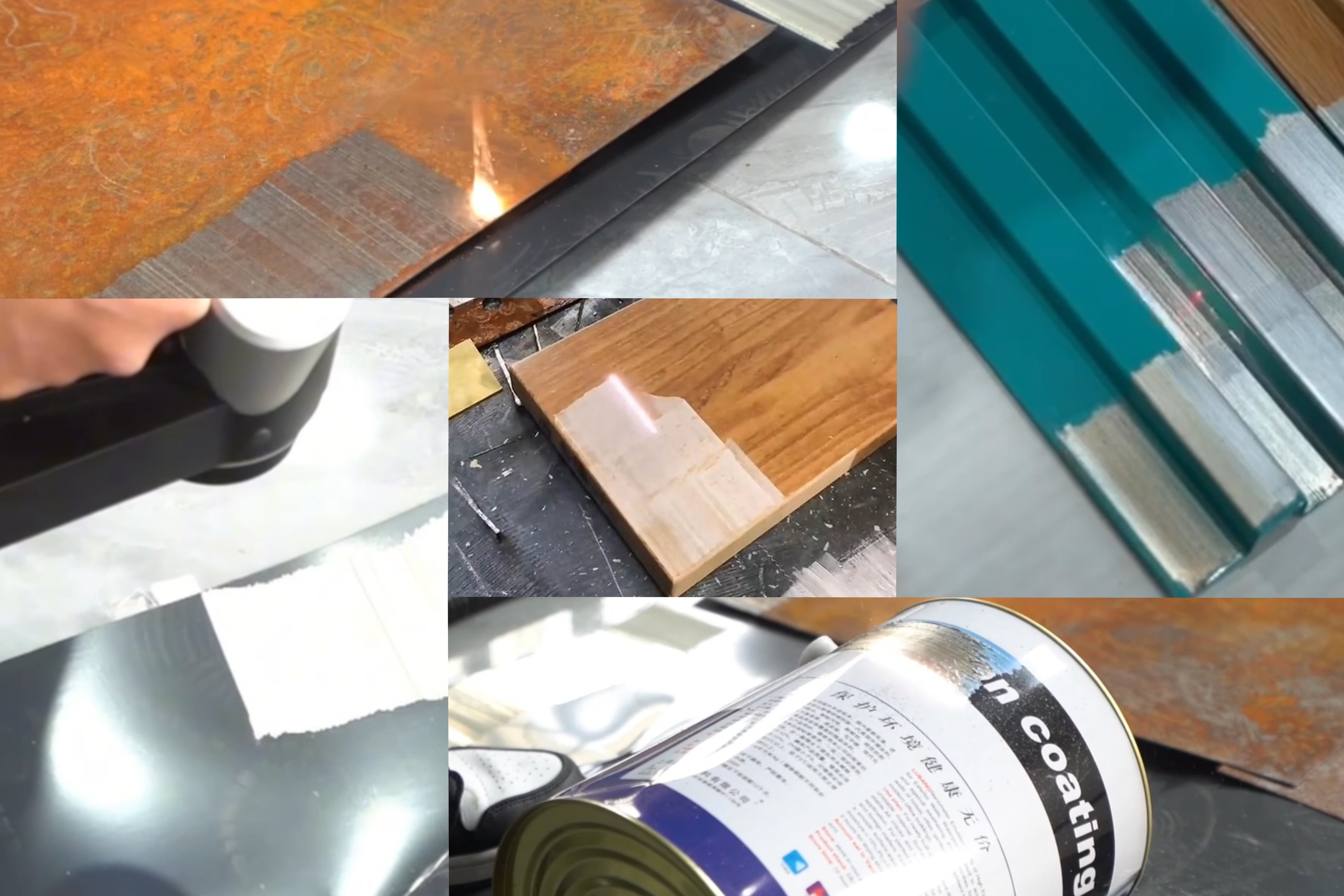

Material Compatibility of Laser Cleaning Machine

When picking a good laser cleaning machine, matching it to your material is vital. Each material needs the right laser type and power for safe, clean results. Here are the key points I consider for material matching:

Laser Parameter Adjustments

- I adjust settings like laser power, pulse time, spot size, and scanning width based on need. For example:

- Metals (e.g., stainless steel, aluminum): Need higher laser power, 1500W–3000W, with pulse frequency of 20–200 kHz and scanning width of 10–270 mm.

- Sensitive materials (e.g., wood, textiles): I use low power to prevent heat damage.

- The right settings improve cleaning and prevent damage.

- Too much power can warp, melt, or damage surfaces, mainly with soft materials. I always use the lowest power needed while keeping the material safe.

Material-Specific Laser Cleaning Requirements

| Material | Laser Type Compatibility | Key Considerations |

|---|---|---|

| Metals | Fiber Laser, Continuous Wave | Great for rust/coating removal with no damage; works well for stainless steel or aluminum. |

| Plastics | Fiber Laser, UV Laser | Make sure material is laser-safe; avoid plastics that release toxic fumes like PVC or ABS. |

| Glass | UV Laser, Fiber Laser | Use low power to prevent thermal cracking. |

| Composite Materials | Fiber Laser | Watch settings for safety; fibers/resins may release harmful fumes when heated. |

| Wood | CO2 Laser | Good for natural wood; engineered woods like MDF may need more testing. |

| Rubber | Fiber Laser | Avoid overheating to prevent burning; good for residue removal. |

Examples and Insights

- High-efficiency cleaning on metals: Carbon steel and stainless steel can be cleaned at rates up to 12 m²/h using a fiber laser.

- Incompatibility: PVC, ABS, and polystyrene release harmful toxins or get damaged, making them bad choices for laser cleaning.

- Delicate textiles: Low-powered lasers clean delicate fibers without harm. I avoid materials that catch fire easily, like polystyrene foam.

By checking material compatibility and setting the right laser power, you can clean well while keeping your materials in good shape for many uses.

Moving Your Cleaning Machine Around

Carry Options

- Laser cleaning machines come in many shapes to fit your needs.

- The MaxWave MW-LC200 Backpack Laser Cleaning Machine weighs 53 Kg and has straps to carry it. It works great in small spaces or places without power.

- Laserax makes cabinets on wheels that you can push to different work spots.

- The MW-LY200 Portable Laser Cleaner comes with a lightweight cleaning head and is set on wheels. I find them perfect for small spaces or mobile cleaning.

How Much They Weigh

- Light models like the MW-LC200 backpack weigh about 53 Kg.

- Heavy-duty machines weigh 100-200 kg. They deliver more power but stay steady with mobile bases for easy setup.

Cleaning Heads That Work for You

- The MaxWave MW-LY200 models have a 0.7 kg head that won’t tire your arm during long jobs.

- I’ve seen Laserax systems with bendable arms that turn and tilt, reaching up to 2.5 meters for better access.

Works in Many Places

- MX-LC200’s battery models allow wireless operation. I recommend these for remote sites with no power.

- The SFX models have a strong outer shell that stands up to bumps during travel or use in tough settings.

Safety Features and Easy Transport

- Wheeled machines have locks on their wheels for stability when working or moving.

- Many come with two-hand start switches and space to store safety gear, making them safer and easier to transport.

Looking at these features helps you pick a machine that fits how you’ll move it, where you’ll use it, and what you’ll clean with it.

Cost Considerations of Laser Cleaning Machine

Picking the right laser cleaning machine means looking at all costs. Let’s break down what you’ll pay upfront and over time:

Price Range by Power Level and Machine Type

- Handheld Laser Cleaners (by power and build quality):

- 100W: Good for light cleaning like grime removal, costs $5,000–$6,500.

- 200W: Works for light rust or paint removal, costs $7,000–$9,000.

- 300W: Handles medium rust or paint jobs, costs $8,500–$11,000.

- 500W Pulsed: For industrial use, costs $20,000–$21,000.

- 1000W Continuous-Wave: Affordable option for rust removal, costs $3,000–$3,500.

- Industrial-Grade Machines:

- Top models start at $50,000 and can go over $200,000, based on power and automation.

Other Costs to Think About

- Training: Manufacturers offer training on safe use of the machines. Costs vary, but some manufacturers, like MaxWave, offer complete and free technical training to their customers.

- Add-ons: Things like robot arms or automation make machines more expensive.

- Following Rules: Meeting green standards costs more at first but saves money later.

By looking at both purchase and running costs, plus long-term savings, you can figure out the total cost. This helps you choose a machine that fits your cleaning needs.

Summary

A reliable laser cleaning machine isn’t just a tool—it’s a long-term partner in efficiency, quality, and growth. Choosing the right one means fewer breakdowns, smoother operations, and faster returns on your investment. So why settle for guesswork when you can invest with confidence? At Maxwave, we offer high-performance, thoroughly tested laser cleaning machines trusted by businesses worldwide. Ready to upgrade your cleaning process? Talk to our experts today and find the perfect solution tailored to your needs.

Recent Comments