Choosing the right laser marking machine can be a game-changer for your business, transforming your production efficiency and product quality. Imagine a machine that not only delivers precision and speed but also saves you time and money in the long run. With so many options available, the key to making an informed decision lies in understanding what makes a machine truly reliable. In this guide, we’ll walk you through the essential factors to consider, ensuring you pick a machine that matches your needs and helps your business thrive.

Points to consider of Laser Marking Machine

Picking a laser marking machine, I find these key factors help you find equipment that meets your needs and works well.

Understand Different Laser Types and Material Compatibility

- Fiber Lasers: Great for metals like aluminum, copper, and steel, plus some non-metals like rubber and plastics.

Example: A fiber laser at 1.064 µm is common in car and airplane industries because it marks metal cleanly. - CO2 Lasers: Work best on non-metal materials like wood, acrylic, glass, paper, and fabric.

- UV Lasers: Perfect for delicate materials like ceramics, glass, and some plastics.

Example: UV lasers at 355 nm can mark electronics without heat damage.

Assess Speed for Productivity

Speed matters for busy industries:

– A 30W fiber laser marks small designs (110 mm × 110 mm logos) well. Larger designs (400 mm × 400 mm) need more power like 100W for best results.

– Note: Use laser annealing for long-lasting metal marks. Use etching when you need speed.

Ensure Software Flexibility and Integration

Easy-to-use software helps you make quick changes and connect with production lines.

Example: Wi-Fi-ready systems let you control marking from afar, helping large factories work better.

Factor in Maintenance and Durability

Fiber lasers use air cooling, making them easier to maintain than CO2 lasers. You need to clean regularly to stop buildup when working with messy materials like rubber and wood.

Consider Long-Term Investment Costs

Buying high-quality, durable machines cuts down on ownership and repair costs over time.

Example: A UV laser costs more upfront but offers better quality and less maintenance, giving better value over five years.

1. Know What You Need for Marking

I find that picking the right laser marking machine starts with knowing exactly what you need. Here’s how I suggest you figure this out:

Production Volume

- For small jobs, I recommend tabletop or portable systems. They save money and space.

- For large-scale production, go with an inline system in your production lines. This gives faster output and steady marking.

Speed Needs

- Fast systems help you handle big batches and meet due dates.

- Moving-target marking works great with conveyor belts to boost output.

Space Limits

- Small, air-cooled systems fit in tight spaces.

- Check that your area has good air flow and power for the best results.

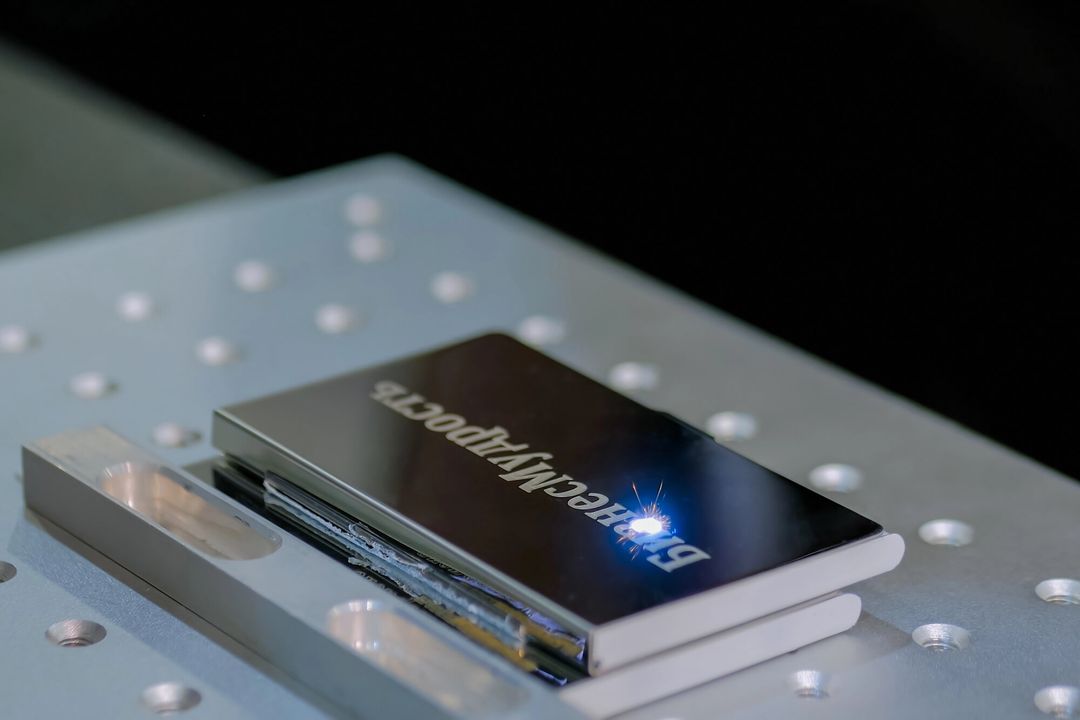

Mark Quality

- For clear, sharp marks, you need high-precision lasers.

- The right laser type matters for shiny or heat-proof materials.

I’ve spent a lot of time studying this field and found that using these criteria helps guide your laser marker choice. When I think about these points, I get clear direction that cuts through confusion and helps me find the right machine.

2. Assess Laser Marking Machine Power and Wavelength

As choosing a good laser marking machine, I find that power and wavelength are key factors that affect marking depth, speed, contrast, and what materials you can use. Here’s my breakdown:

Power Considerations

- Low Power (20W to 30W):

Great for exact marking on plastics and metals. These lasers create fine details with shallow marks, saving money when you don’t need deep cuts. They won’t work well for deep cutting or fast factory jobs.

Example: I’ve seen a 20W fiber laser make clean, sharp shallow marks on aluminum. - Medium Power (50W):

Best for deep marks on hard metals like brass or steel, and some cutting jobs. These work faster but make more heat. The heat can harm some plastics.

Example: A 50W laser cuts deeper and works faster than a 30W, but can melt plastic during use. - High Power (75W to 100W):

Good for tough jobs like deep cutting thick metals. These aren’t as good for small, detailed work and cost more than you might need.

Example: A 100W laser cuts thick metals well but isn’t precise enough for fine marks on gold.

Wavelength Considerations

- 1064nm (Fiber and Nd:YAG Lasers): Good for metals because they absorb this light well, creating clear marks.

- 355nm (UV Lasers): Works best on plastics and glass. The short waves have more energy, making clean marks without damage.

- 532nm (Green Lasers): Made for shiny materials like gold and copper.

In my view, picking the right power and wavelength makes sure your laser works well with your materials and needs, giving you good results at a fair prihttps://www.lasermaxwave.com/laser-marking-machine-3/ce.

3. Laser Marking Machine Software and Ease of Use

I think checking the software and how easy it is to use should be your first step when picking a laser marking machine. Good software boosts your output and makes operations run smoother. Here’s what I look for:

Simple Interfaces

A simple interface helps operators of all skill levels. For example: – MaxWave has a clear interface with vision features for exact alignment. – Beamer Laser Systems offers “Marking Creator 3.0,” with a simple interface for quick setup.

Good Parameter Control

Good software lets you adjust laser settings like power and speed: – Beamer’s “Parameter Finder” finds the best material settings. – MaxWave Software gives you control over laser power and speed for different uses.

Special Productivity Features

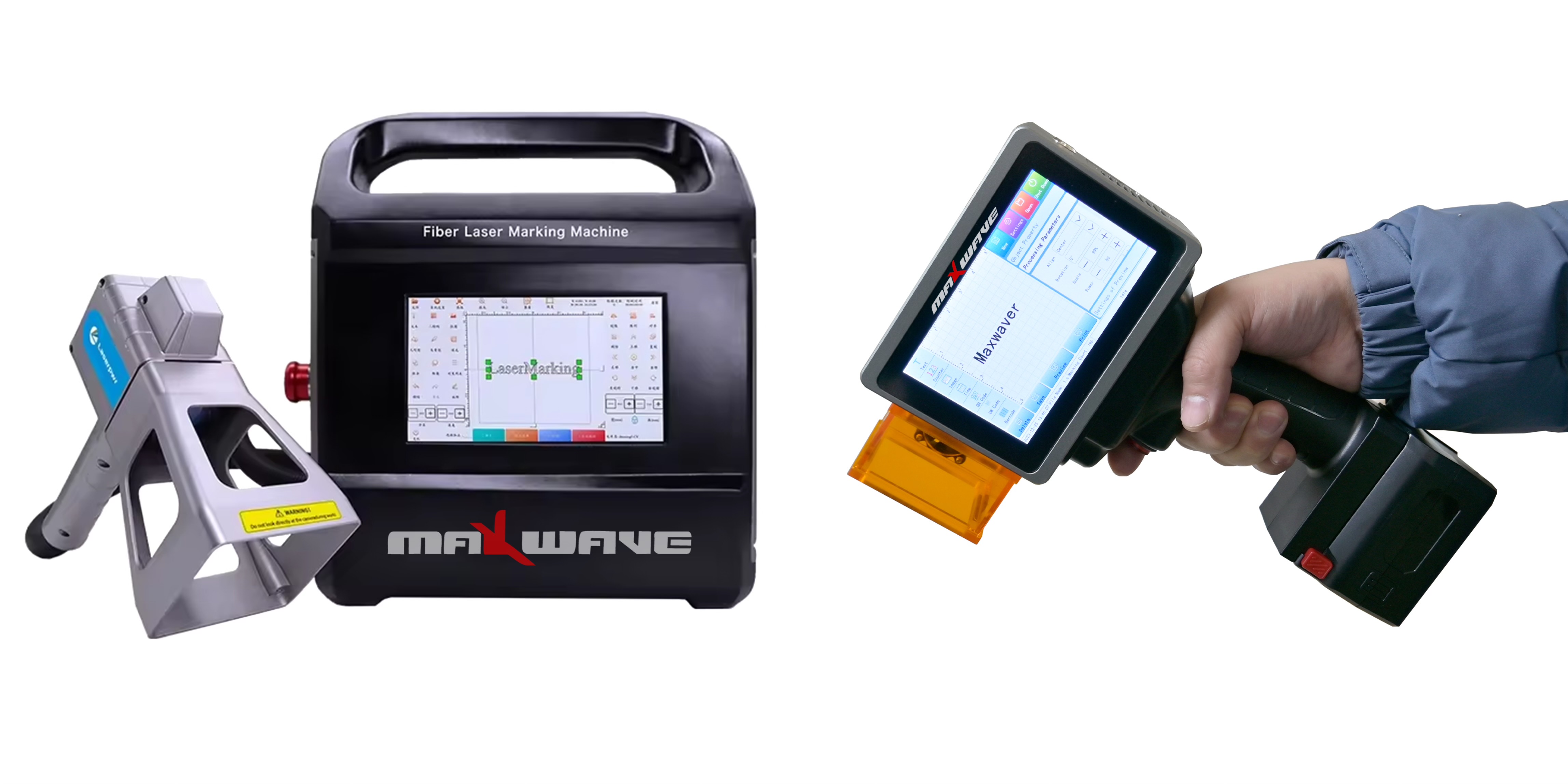

Modern software makes complex tasks easier: – FOBA’s “MOSAIC” marks without fixtures, improving speed. – MaxWave supports both desktop and handheld use, with a detachable handle for flexible and convenient operation.

I’ve found that looking at ease of use, features, and integration helps companies get better results. One aerospace company switched to MaxWave’s laser marking system with custom interfaces. They cut costs and improved tracking. I believe picking the right software is key for long-term success.

4. Laser Marking Machine Design

Smart design choices lay the foundation for long-term performance, precision, and safety, ensuring your laser marking machine runs efficiently, requires less maintenance, and delivers consistent results—no matter the task or environment.

Structural Stability

For better marking precision, choose a machine with a strong, stable frame to reduce vibrations. Opt for models with reinforced support columns and worktables equipped with clamps or guide bars—these features help secure your materials, prevent errors, and ensure consistent results.

Compactness and Portability

For limited spaces or on-the-go tasks, compact laser marking machines or portable fiber laser markers are an excellent choice. Easy to carry and set up, these versatile tools let you mark wherever you need—without sacrificing precision or performance. Whether you’re working in a small workshop or providing mobile services, portability makes all the difference.

Protective Features

Safety should always come first—look for machines with protective covers that block harmful laser light and fumes. A reliable exhaust system is also a must, helping to clear away dust, smoke, and gases so you can work in a cleaner, healthier environment while keeping your machine in top condition.

Accessibility to Components

Machines with easy access to parts like laser arms, galvo heads, and cables make maintenance faster and more straightforward. This kind of design helps reduce downtime and keeps your production running smoothly.

I believe focusing on these design and installation steps will help you improve the performance, accuracy, and safety of your laser marking machine for years to come.

5. ROI & Market Growth of Laser Markers

I find that knowing the cost and possible profits is key when buying a laser marking machine. Here’s my breakdown:

Maximizing ROI

Investing in a laser marking machine offers a high return on investment. With a lifespan of over 100,000 hours and minimal consumables, these machines significantly lower long-term operating costs. They provide 30% faster processing speeds and 0.01mm marking precision, reducing rework and waste. Laser marking also meets the growing demand for product traceability, anti-counterfeiting, and customization, helping businesses recover costs within 6–12 months and increase product value.

Market Demand and Trends

In 2025, the global laser marking machine market is expected to grow to $3.38 billion, up from $3.22 billion in 2024, reflecting the continued demand for high-precision and durable marking solutions.

The Asia-Pacific region will remain the market leader, accounting for 38.3% of the global market share, valued at approximately $1.3 billion in 2024. This growth is driven by the rapid expansion of manufacturing in China and India. Furthermore, increasing demand for automation and efficient production in industries like automotive, electronics, and medical devices will boost the adoption of laser marking technology. With stricter environmental regulations, there is a rising demand for low-energy, pollution-free marking technologies, further accelerating market growth.

6.Laser Marking Support & Warranty

Buying a laser marking machine, I recommend checking the warranty and support options carefully. This helps ensure your machine stays reliable. Here’s what to look for:

Technical Support Services

Many companies provide basic support through remote troubleshooting via email or video calls. However, on-site repairs usually incur additional costs, including technician fees and travel expenses for machines no longer covered by warranty. Brands like MaxWave, on the other hand, continue to offer lifetime guidance through email or phone even after the warranty period expires, though replacement parts and repairs will need to be paid for separately.

Brands and Warranty Examples

- LaserTech USA: Gives a 2-year defect warranty but excludes wear items. They charge $160/hour for on-site techs, with optional extended plans.

- Thunder Laser USA: Offers a 2-year warranty for the laser source and 1-year for accessories and includes good training resources.

- OMTech: Gives a 2-year warranty for fiber laser machine parts, with extra-cost support after warranty ends.

Conclusion

Ready to take your business to the next level? Investing in a high-quality laser marking machine is not just about staying competitive; it’s about ensuring your products stand out with precision and innovation. With the right machine, you’ll enjoy faster processing, lower costs, and the flexibility to meet all your marking needs. Don’t settle for less—choose a solution that offers long-term value and helps your brand grow. Make the smart choice today and unlock the full potential of your business with advanced laser technology! For more details about laser marking machine or to get a quote, contact us today!

Recent Comments