Finding the perfect jewelry laser welder can be a game-changer for your workshop, unlocking endless possibilities for intricate designs and flawless repairs. Whether you’re crafting delicate pieces or tackling complex fixes, the right machine will make your work smoother, faster, and more precise. In this guide, we’ll walk you through everything you need to know to choose the ideal welder that fits your style, space, and workflow.

Power and Applications of Jewelry Laser Welders

Power output is a key factor when I choose a jewelry laser welder. This tells you what jobs the machine can do well. We measure power in watts (W) for steady output. Peak power during pulses can hit several kilowatts (kW).

Common Power Output Ranges & Their Applications

60W–100W

If you work with fine jewelry—like delicate repairs or prong re-tipping near gemstones—this range is ideal. The LaserStar 993 iWeld 60W, for example, offers 11kW peak power, 180J pulse energy, and can run 24/7. With burst and speed modes, it’s perfect for precise, all-day welding.

150W–200W

These machines are highly versatile—great for all kinds of jewelry work and even light industrial tasks. With pulse energies up to 225J and peak power around 9–12kW, they’re powerful enough for jobs like resizing bracelets, fixing eyeglass frames, or small dental repairs. The ZAC 150W, for example, offers adjustable spot sizes (0.2–2mm) and works smoothly on gold, silver, and platinum.

100W–150W with High Peak Pulse (up to 12kW)

This range is great for shops that need high welding power—perfect for deep welds, tough materials like platinum or titanium, and complex repairs. The Orotig Revo X², for example, delivers 150W average power, 12kW peak, and up to 280J pulse energy. It’s built for busy workshops and demanding daily work.

Choosing a jewelry laser welder with the right power is key. It helps you handle everything from small repairs to heavy workloads. This affects your shop’s work quality and how much money you make.

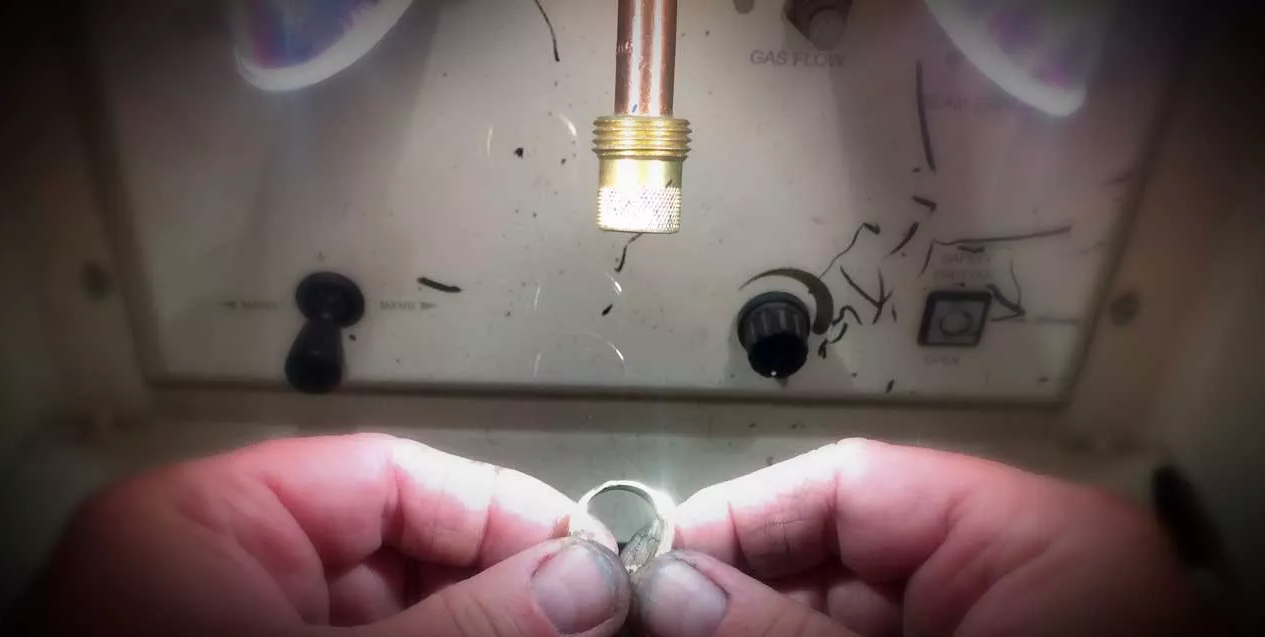

Jewelry Laser Welder: Pulse and Spot Control

I find that getting precise jewelry laser welder requires adjustable pulse settings and spot size control. These features affect weld quality, accuracy, and how much heat reaches sensitive parts. When you choose a laser welder for your shop, I suggest you look closely at these controls.

Adjustable Pulse Settings for Jewelry Laser Welder Precision

Advanced jewelry laser welders allow you to adjust pulse width (0.1–20 ms), frequency (1–50 Hz), and energy (40J–280J) for different tasks. Lower pulse settings help protect delicate areas like thin chains and gemstones. Touchscreen controls make precise adjustments easy, speeding up workflow and reducing mistakes.

Variable Spot Size for Laser Welding Accuracy

Jewelry laser welders let you adjust the spot size, usually between 0.05 mm and 2.5 mm. A smaller spot concentrates energy for more precise welds—crucial for delicate tasks like prongs or jump rings. For example, a 0.14 mm spot can weld 60% faster and 16% deeper than a 0.4 mm one. Digital or dial controls make it easy to switch between different metals and repair types.

From my perspective, good control over pulse settings and spot size is essential. It helps you make precise, dependable welds in your jewelry workshop.

Jewelry Laser Welder Controls & Comfort

A jewelry laser welder’s controls and comfortable design are important. They help improve workshop output, make work accurate, and keep operators healthy. I find that as technology gets better, operators want controls that are easier to use. They also want to see what’s happening in real time and be comfortable during long work hours.

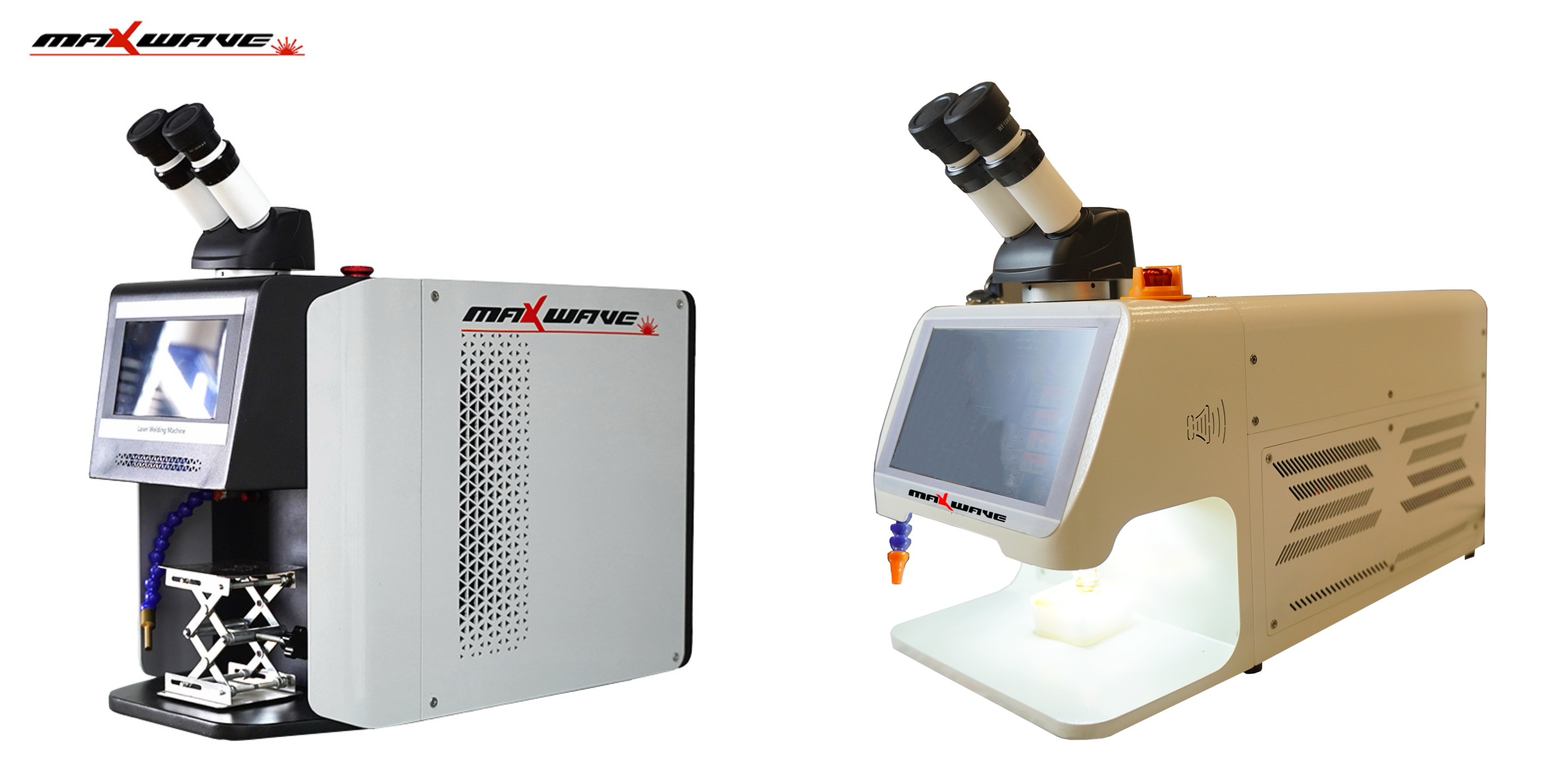

Touchscreen Displays and Intuitive Controls

I recommend advanced laser welders with color touchscreens (3.5 to 9 inches) for easy adjustments and quick access to settings. Machines like the MaxWave MW-QW60/120/200 and Orotig MIDI TECH offer clear, responsive screens that display settings and allow real-time monitoring. Many also feature dual control options with both touchscreen and foot pedal, making it easier to maintain precision during fine repairs.

Preset and Adjustable Parameters

Many welders come with preset settings that are suitable for common jewelry metals, but for specific or delicate tasks, users can fine-tune power, pulse width, frequency, energy, spot size (down to 0.1 mm), and focus position. This level of control is essential for precise work. Machines like the MaxWave MW-QW allow users to manage six key welding settings from a single control panel, reducing the need to stop work frequently.

Ergonomic Design Elements

- Features like wide-access welding chambers and cushioned armrests (like on the iWeld Benchtop 993) help operators maintain a comfortable posture. Working long hours becomes less physically straining.

- Internal wrist and armrest cushions are important. Adjustable workspaces (found on Orotig, MaxWave) also help. Based on my experience, these features help prevent repetitive strain injuries. They allow operators to position themselves comfortably.

- Compact, lightweight machines save space on the workbench. They are also easy to move for different workshop layouts or mobile work.

- Universal wheels allow you to reposition the welder quickly in a busy workshop.

- Well-designed control layouts mean operators don’t have to move much to reach controls, displays, or vision systems. This benefits both left- and right-handed users.

I suggest choosing a jewelry laser welder with these user interface and comfort features. It will greatly improve your workshop’s efficiency, the quality of your welds, operator comfort, and overall workplace safety.

Jewelry Laser Welder Cooling

In my experience, the cooling system is crucial when selecting a jewelry laser welder. It affects performance, reliability, and efficiency. Choosing the right cooling method ensures longer machine life and better welding results.

Types of Cooling Systems

- Air Cooling

Air cooling systems, using fans to remove heat, are common in lower-power or portable welders (up to 150W). These machines, like MaxWave MW-QW200, are lightweight (around 32 kg) and portable, making them great for jewelers on the go or with small shops. They’re easy to set up, require no water tanks, and need minimal maintenance—just cleaning the fans and ducts. They also offer a lower cost and simpler design.

- Water Cooling / Built-in Water Cooler

Water-cooled machines like the ZAC 200W and SFX LJW-200 are ideal for high-power welding (200W+). They provide better cooling, prevent overheating, and are built with durable stainless steel parts. These systems include advanced monitoring tools for water filters and pressure. Though heavier (around 180 kg), they’re great for busy workshops but require regular maintenance, water quality checks, and have a higher initial cost.

Air-cooled laser welders are great for light, portable use with minimal upkeep. For high-power, long-term work, water-cooled systems are better—they offer stable temperature control, improved safety, and longer machine life.

Jewelry Laser Welder: Size and Fit

I believe finding the right jewelry laser welder means thinking about its size first. You need to see how it will fit in your workshop. This is very important for small jewelry shops or home studios. Retail spaces also need careful space planning.

Typical Machine Sizes and Weights

Let’s look at common jewelry laser welders. Pay attention to their sizes and weights:

- Benchtop models (e.g., iWeld 993 Series): The machine has dimensions of 33”L x 21”W x 16”H (839mm x 534mm x 406mm) and weighs about 125 lbs (57 kg). The chamber size is 10”L x 20”W x 9”H (254mm x 508mm x 229mm). It is ideal for most jewelry tasks and portable enough to fit on workbenches.

- Standard desktop welders (e.g., SFX LJW-150/LJW-200): The 150W model measures 1000×600×700mm and weighs 103 kg, while the 200W model is 1100×700×1300mm and weighs 180 kg. You’ll need approximately 1.1m x 0.7m of floor space and at least 1.3m of height clearance.

- Mini and lightweight models (e.g., MW-QW Series): These models measures 610 mm in length, 290 mm in width, and 430 mm in height, weighing 32 kg. They are designed for easy mobility, making them ideal for transport or repositioning.

Key Workspace Fit Considerations

Ensure the machine fits properly in its designated space without obstructing walkways or work areas. Machines with a small base and wheels are easier to move, making them ideal for shared studios or flexible layouts. For added comfort, look for features like built-in microscopes, user-friendly touchscreens, and adjustable working heights to reduce fatigue.

If your space is tight, smaller laser welders are a good starting point. But, from my perspective, don’t sacrifice key features. You must have a chamber big enough for your largest jewelry items. Also, prioritize controls that allow you to work comfortably and efficiently.

Jewelry Laser Welder: Reliability and Brand Support

If you’re picking a jewelry laser welder for your shop, I think reliability, service after the sale, and the brand’s name are very important things to look at. These points affect the quality of your welds. They also impact how happy your customers are over time and how smoothly your workshop runs.

Service, Support, and Maintenance

Many laser welders have easy-to-replace parts, cutting downtime and reducing waste. Their simple design makes them more reliable and easier to maintain. Trusted brands like MaxWave also offer better support, with fast, expert help directly from the manufacturer.

Brand Reputation

Top brands give consistent welds. Based on what jewelers say, brands like Sunstone, MaxWave, and Orion make machines that weld the same way every time. I believe this is very important because your reputation depends on quality work.

Generic machines can cause problems. People using cheaper or no-name welders report that welds are not always consistent. There’s a higher chance of machine failure, even with the same settings. I think these problems can hurt how people see your workshop and cost you more money later.

Summary

Choosing the right jewelry laser welder isn’t just an investment; it’s a game-changer for your craft. With the right machine, you’ll create flawless pieces, save time, and impress clients with top-tier results. Ready to elevate your workshop and stand out from the competition? Let’s find your perfect welder today! For more details about jewelry laser welder or to get a quote, contact us today!

Recent Comments