Choosing the right welding method for jewelry repairs and designs can make all the difference in the final result. While traditional soldering has been the go-to method for many years, laser welding is quickly gaining popularity for its precision, speed, and safety benefits. But does it really surpass soldering? In this article, we’ll explore the strengths and weaknesses of both techniques to help you determine which one is the best choice for your jewelry-making needs.

Overview of Two Welding Methods

From my experience, jewelry repair and making often involve two main ways to join metal: laser welding and traditional soldering. I find each technique has its own good points, uses, and downsides. This makes them right for different types of repairs or making jewelry.

What Is Laser Welding in Jewelry?

Jewelry laser welder uses a precise, focused beam to melt and join metal exactly where needed. The result is a nearly invisible, smooth repair that’s up to three times stronger than the original metal—and over 250 times stronger than solder. It keeps heat localized, protecting delicate gems and materials. Using matching filler wire ensures color consistency and durability. Plus, with minimal heat spread, there’s very little cleanup required.

What Is Traditional Soldering in Jewelry?

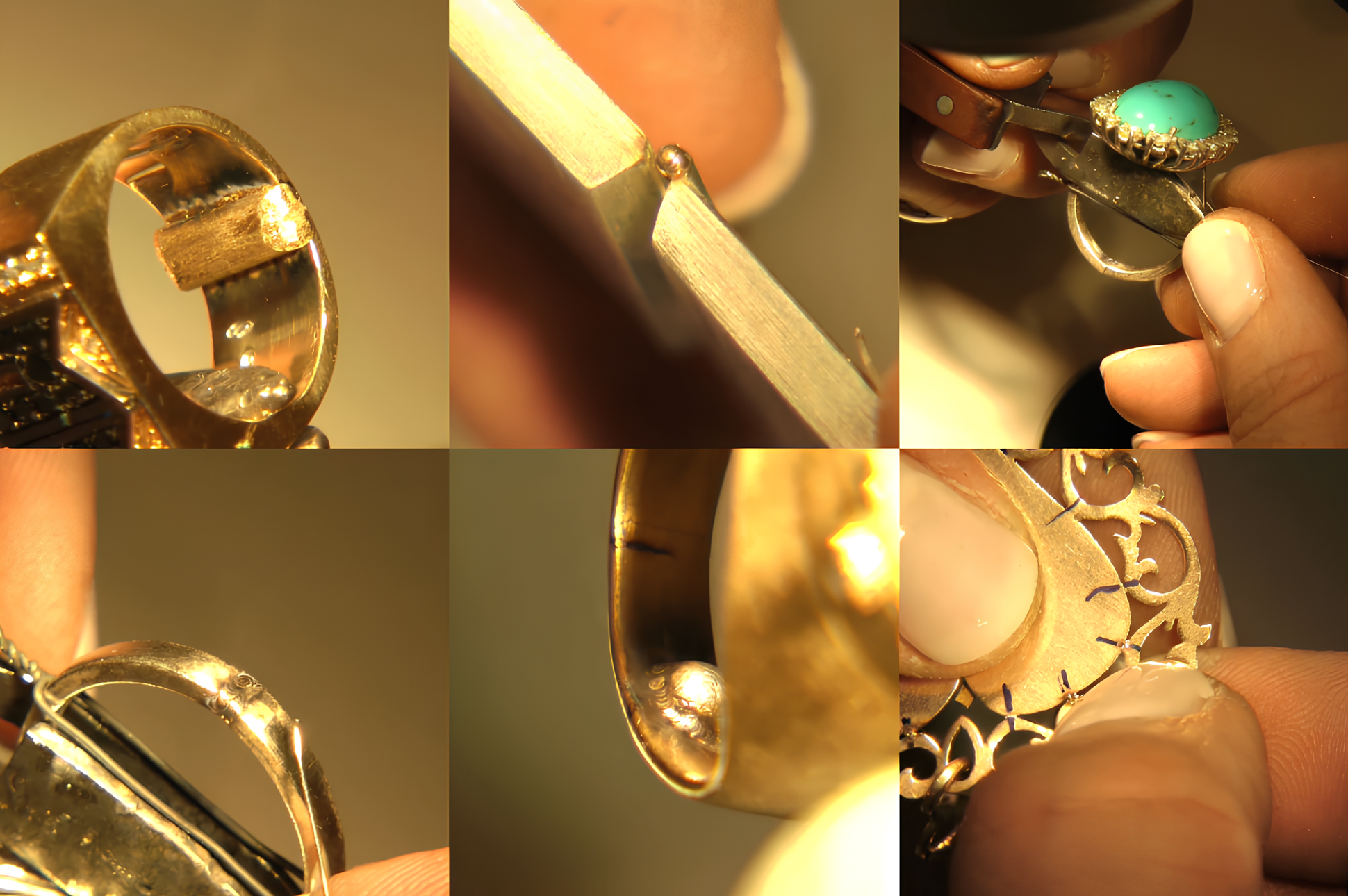

Soldering uses a torch to melt filler metal and join parts, but the joints are weaker and may discolor or fail over time. The heat spreads widely, risking damage to nearby stones and causing visible seams or fire scale. It often requires removing delicate parts and adds extra cleanup after the repair.

Comparison of Laser Welding and Traditional Soldering: Key Points

- Precision: Jewelry laser welder lets you make tiny repairs. Think fixing ring prongs, mending thin chains, or resizing platinum bands. There’s little risk to nearby parts. Soldering works best for simpler joins where pinpoint accuracy isn’t the top priority.

- Speed & Efficiency: Jewelry laser welder is quick. I can resize a ring or fix a chain in minutes sometimes, with little finishing needed. Soldering takes longer. It also requires a lot of cleaning because of the flux and extra solder.

- Versatility: Jewelry laser welder is great because it works on many metals. You can use it on gold, silver, platinum, stainless steel, titanium, and others.

- Cost: Soldering tools cost less upfront. However, the work takes more time and effort. The results often don’t look as clean as laser welding, in my opinion.

- Hybrid Use: Many jewelers today use both methods. I recommend using jewelry laser welder for detailed, visible spots. Soldering can work well for larger areas that won’t be seen, like inside a vintage brooch repair.

Industry Adoption and Real-World Examples

Since the late 2000s, desktop laser welders have become popular in jewelry workshops for their speed, compact size, and precision. Jewelers use them for delicate tasks like fixing prongs near diamonds, resizing platinum rings, and repairing tiny chains—all with less risk and minimal cleanup.

In short, both jewelry laser welder and soldering are useful, but I find laser welding better for its strength, precision, speed, and clean finish. It’s ideal for high-quality, detailed work, while soldering still works well for simpler, budget-friendly repairs.

My Thoughts on Jewelry Welding Processes

When I assemble or repair jewelry, I find there are two main ways to do it: jewelry laser welder and traditional soldering. Both methods join metal parts. However, I’ve noticed they work quite differently in terms of the steps involved, how heat affects the piece, speed, and what jobs they are best for.

How I See the Jewelry Laser Welding Process

- Process: Jewelry laser welding machine uses a precise, high-energy beam to melt and join metal exactly where needed, often without filler. With tools like microscopes for aiming, it creates tiny, strong welds while keeping surrounding areas cool. This protects delicate parts like gemstones and avoids bending or marking the surface—making repairs faster and cleaner without needing to remove sensitive components.

- It’s fast: I notice each weld takes less than a second. Repairs get done quicker compared to soldering. Clean-up after welding is minimal or unnecessary in my experience because there isn’t the oxidation, fire scale, or extra solder you get with traditional methods.

- Works on many materials: I can use it on gold, platinum, silver, titanium, and pieces made of mixed metals.

My View on the Traditional Jewelry Soldering Process

- Process: Soldering joins metals using a filler called solder, which melts at a lower temperature. I place small pieces with flux to prevent oxidation, then heat the area with a torch. The solder flows into the gap and bonds the metals as it cools. Since it’s a different metal mix, the joint may look slightly different and isn’t as strong as the original metal.

- Heat spreads over a wider area. From my perspective, this raises the chance of fire scale, color changes, bending, or damage to nearby stones and thin parts. I often find it necessary to remove or protect heat-sensitive components first.

- Tools and supplies I need include torches (like gas or oxy-acetylene), soldering blocks, tweezers, different solder types (hard, medium, easy), and flux.

- Choosing solder: For pieces needing multiple joins, I might use several types of solder, starting with the hardest (highest melting point). This approach helps prevent earlier joins from melting when I heat the next spot.

In short, jewelry laser welder offers fast, precise joins with minimal heat, making it ideal for delicate jewelry and mixed metals. Soldering is still useful and flexible but slower, with more heat spread and greater risk to fragile parts.

Strength and Durability of Two Welding Methods

In my experience, when we compare jewelry laser welder and traditional soldering, strength and durability are key points to consider.

Key Differences in Strength

- Soldering: It is more affordable and easier to reverse, but it creates weaker joints with visible seams that can degrade over time, leading to more frequent repairs.

- Laser Welding: Laser welding machine requires a higher upfront cost and skilled technicians, but it delivers stronger, longer-lasting connections.

Advantages of Laser Welding for Strength and Durability

- Joints almost as strong as the original metal. This is vital for items like rings, bracelets, or watchbands.

- Minimal heat-affected zone: It doesn’t weaken or discolor the nearby metal.

- Filler wire matches the main metal: It fills gaps and strengthens the piece without hurting its strength or look.

- No visible seams or color change at the joint: This keeps the piece strong and looking good.

From my perspective, jewelry laser welder performs better than traditional soldering for strength and durability. I suggest it’s the better choice for most structural jewelry repairs and pieces you wear often.

Two Welding Methods Precision and Looks

In my experience, jewelry laser welder offers better precision and looks than traditional soldering. I find the focused laser beam lets me target tiny spots. This helps when working on detailed designs or making tricky repairs near gems. It creates smooth joints without harming nearby areas or materials.

Laser Welding: Higher precision and better surface finishg

- Invisible Joints: Jewelry laser welder creates a smooth finish. People really value this in expensive or custom jewelry.

- Stronger Connections: Tests show laser welds are strong, up to 95% of the original metal’s strength. I find they are much stronger than solder – up to 260 times stronger.

- Fewer Flaws: There’s less chance of gaps or small holes compared to soldering. This gives a clean, perfect look.

- Works with More Metals: Lasers join many metals like platinum, gold, silver, and titanium. They even join different metals together well. I think this gives designers more creative options.

Traditional Soldering: Where It Doesn’t Measure Up

- Marks and Color Changes: Soldering can leave lines and seams you can see. This happens more if you use too much solder or if the heat changes how the metal or stones look.

- Higher Damage Risk: The wide heat from soldering increases the risk. It can damage thin metal, fine details, or nearby gems.

- More Finishing Needed: Soldered joints usually need more polishing and blending to look good. In my experience, this takes more time and costs more.

I believe jewelry laser welder is the best choice for precision and appearance in making and repairing jewelry. I recommend it for expensive, delicate, or complex pieces. Soldering is still useful for simpler jobs, handcrafting, or when cost is the main concern. But, I find it doesn’t give the same smooth results or protect gems like laser technology does.

Safety and Risks of Two Welding Methods

Jewelry laser welder and traditional soldering both have unique safety risks at work. I think it’s important to understand these differences.

Jewelry Laser Welding

Jewelry laser welder is safer because it generates minimal fumes, smoke, and heat, reducing the risk of burns or fire. The laser’s focused beam limits heat exposure, which protects surrounding materials like gemstones. Since it’s a non-contact process, there’s less chance of damaging the jewelry during repairs.

Traditional Soldering

Soldering poses more risks, as the torch creates heat that spreads, potentially damaging nearby materials, including gemstones, or causing discoloration and warping of metals. There’s also a higher risk of burns and fire due to the open flame, and additional cleaning work is often needed after the process.

While traditional soldering has its uses, laser welding offers a safer, more precise, and efficient option for high-quality, durable repairs and designs.

Conclusion

Whether you’re a seasoned jeweler or just starting your business, choosing the right welding technique can elevate your craft. While traditional soldering has its place, the power of jewelry laser welder can’t be overlooked. Offering unmatched precision, speed, and durability, laser welders are revolutionizing the way jewelry is made and repaired. If you’re ready to step up your game and deliver top-tier results, it might just be time to make the investment. Don’t miss out on the future of jewelry craftsmanship—upgrade to laser welding today! For more details about jewelry laser welder or to get a quote, contact us today!

Recent Comments