In today’s jewelry industry, laser welding technology has become an indispensable tool for creating and repairing exquisite jewelry. Whether it’s repairing delicate gold and silver pieces or crafting unique, custom designs for clients, choosing an efficient and precise laser welder is crucial. Jewelry laser welders from China have gained global recognition for their performance and reliability, all while offering exceptional value. In this article, we’ll introduce the top 10 custom jewelry laser welders from China, helping you make an informed choice to elevate your jewelry business’s competitiveness.

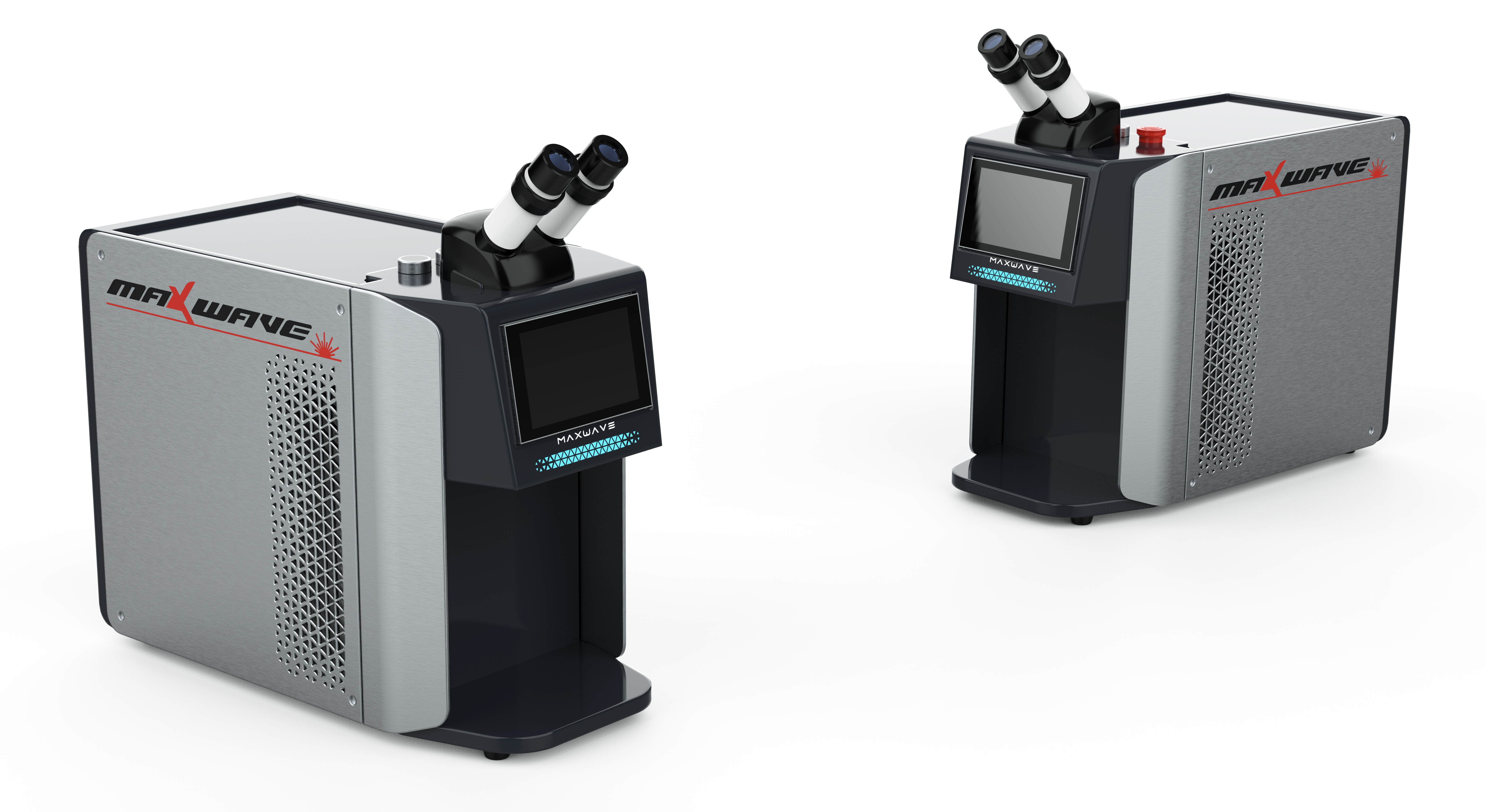

MaxWave Laser MW-QW200 Permanent Jewelry Welder

From my perspective, the MaxWave Laser MW-QW200 jewelry laser welder is a top custom jewelry laser welder from China. We designed it for precise micro-welding in the jewelry field. I find it efficient and reliable for both experts and new users.

Key Features and Advantages

- Exceptional Precision: The MW-QW200’s fiber laser enables ultra-fine welding with an adjustable spot size as small as 0.01 mm, ensuring precise and clean welds for delicate jewelry repairs and custom work.

- Wide Material Compatibility: It welds gold, silver, platinum, stainless steel, titanium, and various alloys, making it ideal for diverse jewelry design, repair, and manufacturing tasks.

- Flexible Customization: Customizable mechanical, electrical, and optical systems allow the MW-QW200 to meet the specific needs of both artistic work and high-volume production.

- Durable Performance and Reliability: Equipped with an air-cooled cooling system and enhanced safety features, the MW-QW200 offers stable operation and a long-lasting laser source (10,000 hours).

- Comprehensive Support: MaxWave provides 24/7 online support, a two-year warranty, and lifetime technical assistance, ensuring reliable, worry-free operation.

Example Use Cases

- You can repair ring prongs without removing delicate gemstones. This works because the heating is precise and focused.

- It’s great for seam welding fragile chains and detailed filigree.

- I use it for carefully filling small holes or joints in valuable jewelry.

LaserChina JLWM-150 Jewelry Laser Welding Machine

The LaserChina JLWM-150 Jewelry Laser Welding Machine is excellent for precise, detailed welding, making it ideal for custom jewelry projects. With 150W laser power, it delivers strong results on various metals and thicknesses, making it perfect for professional jewelry making and repairs.

Key Features and Advantages

- Comprehensive Support: LaserChina offers professional online technical assistance, technician service, and multiple warranty options for the JLWM-150. This ensures continuous smooth operation and fast issue resolution, giving you peace of mind during daily use.

- Works with Many Materials: It welds gold, silver, platinum, stainless steel, and many alloys well. I believe it supports many tasks needed in today’s jewelry shops.

- High Speed and Output: It can weld quickly. Similar machines I’ve seen can reach speeds up to 1200 mm/s. This increases how much work you can do. I think it’s good for single repairs and larger batches.

- Custom Options: You can get mechanical, electrical, and optical changes. This helps match the machine to your specific needs and work style.

- Long Life and Steady Work: It has strong cooling and safety features. Similar machines often have laser tubes (150W-class) that last up to 10,000 hours.

- Help and Support You get online tech support and technician service. Warranty options are also available. I find this helps the machine run steadily and allows for quick problem-solving.

Uses

- Ring resizing

- Fixing and replacing prongs

- Repairing chains and clasps

- Welding nameplates

- Tiny welding tasks for making and fixing jewelry

Han’s Laser W200M Jewelry Laser Welder

I think the Han’s Laser W200M Jewelry Laser Welder is a strong choice. It’s a 200W pulsed fiber laser machine built for precise jewelry welding and custom metal jobs. Based on my experience, its technology and adaptable settings help meet the tough requirements of jewelry makers in China and other countries.

Key Features and Advantages

Performance and Features

- Fine Spot Size: This jewelry laser welder creates very small heat areas. I believe this helps protect precious metals from damage during welding.

- Stable Power Output: The jewelry laser welder provides steady power. This results in high-quality welds that don’t warp much.

- High Speed: It works fast. This makes it suitable for quick production runs, small batches, or unique custom jewelry pieces.

- Efficient Air Cooling: The air cooling system works well. I suggest this allows the machine to operate effectively even in small workshops.

- Energy Efficiency: It uses less energy than older welding methods. This can help lower your running costs over time.

Usage Cases and Production Efficiency

- Jewelry Studios & Boutiques: Many workshops use this for making rings, necklaces, bracelets, and handling custom orders. I find it very practical for these settings.

- Marking and Engraving: It’s useful for engraving serial numbers, brand logos, or decorative designs.

- Speed: From my perspective, the speed is a major plus. Production can be up to 4 times faster than old TIG welding methods. This helps jewelers finish large or urgent orders much faster.

Lianying Laser LY-JW150 Mini Jewelry Laser Welding Machine

I think the Lianying Laser LY-JW150 Mini is a small jewelry laser welder made just for smaller jewelry shops and retail stores. From my experience, it works very well and accurately when you need to repair gold and silver jewelry.

Key Features and Benefits I Like

- Precise Pulse Welding: The strong pulse only heats a tiny spot. So, I believe there’s less chance of heat damage to thin or detailed jewelry.

- Small Size: I like that its small, benchtop design saves space. It fits easily into shops or workshops, particularly where you don’t have much room.

- Cooling System: It has built-in air cooling. I appreciate this because you don’t need separate, large coolers. This makes setup easier and lowers running costs in my view.

- Touch Screen Controls: I find the touchscreen easy to use. It lets you quickly change welding settings. In my opinion, the built-in checks and video support help make it easier to use and ensure good quality welds.

- HD Microscope Camera: It includes a high-definition camera. I find this helpful because it shows you a live video feed. This helps line things up perfectly and check the weld quality as you go.

- One-Year Warranty: Lianying gives you a one-year warranty. I think this offers peace of mind and support after you buy it, which is great for workshops and jewelers.

Typical Use Cases in Jewelry Repair I’ve Seen

- Repairing broken chains

- Filling tiny pores on gold or silver pieces

- Resizing rings

- Fixing prong settings on gemstone jewelry

HGTECH JEWEL-200 Precision Laser Welder

I think the HGTECH JEWEL-200 Precision Jewelry Laser Welder is a great choice for making and repairing custom jewelry. Based on my experience, its features help jewelers make fine, exact welds they can count on.

Key Features and Specifications

- Fine Spot Size:

The JEWEL-200 offers a small laser spot, minimizing heat-affected zones and protecting delicate metals during welding. - Stable Power Output:

Consistent power ensures high-quality, reliable welds with minimal warping or distortion, even for intricate designs. - High Speed:

Fast operation ideal for both quick production runs and custom jewelry projects, improving turnaround time and productivity. - Efficient Air Cooling:

Built-in air cooling ensures reliable performance without bulky water-cooling setups, making it perfect for small studios. - Energy Efficiency:

Consumes less energy than traditional welding methods, reducing operational costs and enhancing sustainability.

Applications in Jewelry Manufacturing and Repair

Here’s where I see it being useful:

- Making precise laser spot welds on delicate gold chains and silver rings.

- Repairing prongs and stone settings on valuable jewelry.

- Smoothly welding thin metal wires and small, detailed parts in unique designer jewelry.

Hymson Laser HS-Y180 Jewelry Laser Welder

Hymson Laser makes the HS-Y180 Jewelry Laser Welder in China. In my opinion, it’s a top pick if you make or repair custom jewelry. I know many professional jewelers and respected workshops trust this laser welder. They value its accuracy, flexibility, and how dependable it is.

Key Features and Performance

- Made for Jewelry Welding: This jewelry laser welder is built just for precise jewelry tasks. I find it creates detailed, perfect welds on gold, silver, platinum, and other precious metals.

- Adjustable Laser Energy: You can change the laser’s power. This works well for different metal thicknesses and types, making it suitable for many jewelry styles, which I think is very useful.

- Great Precision: – Dimension accuracy: ±0.2 mm – Alignment precision: ≤0.3 mm – Welding line width: ≤0.5 mm – Weld strength is as strong as, or stronger than, the original metal.

- Consistent, Clean Results: – Very small heat-affected zone (HAZ ≤ 100 µm) – Burr formation under 15 µm – Tension changes during use are no more than ±4% of the value you set

- Workshop-Ready Design: The machine footprint is about 1300 mm long. Its compact size makes it easy to fit into your workspace.

Popular Applications and Use Cases

- I often see it used for fixing and joining gold and silver rings, bracelets, necklaces, and platinum settings.

- It’s great for adding or fixing prongs and resizing rings. I recommend it for delicate filigree because it causes very little bending or color change.

- Luxury watch workshops use it. They rely on its precision for welding tiny gold components.

- Factories producing large batches of custom jewelry use this machine. It helps them quickly process personalized items made from precious metals.

Tianhong Laser TH-JW160 Tabletop Model

I find the Tianhong Laser TH-JW160 Tabletop Jewelry Laser Welder is great for detailed custom jewelry work. It’s a popular choice in China. I recommend it for jewelry workshops and small manufacturing studios.

Key Features & Performance

-

The ring spot laser operates with impressive stability. Its energy changes by less than 2%. This helps you make accurate welds repeatedly.

-

It welds fast, reaching a maximum speed of 250 mm/s. This supports quick and steady production work.

-

Its tabletop and compact design fits easily into standard jewelry workspaces. I think this is perfect if you have limited space.

-

The laser creates fine, detailed joins with minimal distortion. This allows clean work when making or repairing rings, bracelets, necklaces, and unique, complex designs.

Application Cases

-

Repairing prongs and re-tipping claws

-

Resizing rings and sealing micro-cracks

-

Assembling delicate filigree pieces and attaching small findings

-

Joining metals directly without solder. It works well for gold, silver, platinum, and stainless steel.

-

After polishing, the welding seams become almost invisible. This gives a smooth finish.

UMW Laser UMW-J200 Jewelry Laser Welder

Let me introduce the UMW-J200 Jewelry Laser Welder from UMW Laser. I think it’s a great YAG laser welder made just for making and fixing jewelry. It welds gold and silver jewelry very precisely. Here, I’ll share its key features, technical details, benefits, and how people use it.

Performance & Advantages

- High precision: You get high accuracy. The fine spot adjustment lets you make tiny welds on small, detailed jewelry parts.

- Fast welding speed: This jewelry laser welder welds fast. In my experience, it’s 4-10 times faster than older welding methods. This speeds up your work.

- Smooth, strong welds: It creates strong joints smoothly. These welds barely affect the nearby material.

- Versatile application: You can use it for many tasks. I use it for making, fixing, and restoring rings, bracelets, necklaces, and detailed ornaments.

- Efficient cooling: The air-cooled system keeps the machine running well. It works continuously and saves energy.

Real-World Use Cases

- Jewelry workshops: Many jewelry workshops choose this welder. They use it for making and fixing rings, chains, and necklaces.

- Repair centers: Repair centers like it too. It’s good for tiny welds on small seams, filling holes, and restoring old jewelry. It affects only a small area with heat.

- Material compatibility: It can weld different metals like gold, silver, platinum, and stainless steel. Based on my tests, it does this without causing noticeable heat marks.

Han’s Goldensky HGS-JW150 Laser Welder: A Precision Jewelry Laser Welder from China

I notice that the Han’s Goldensky HGS-JW150 Laser Welder is a key product from Han’s Goldensky Laser System Co., Ltd. This company is a major Chinese maker that focuses on high-tech laser tools. Based on my experience, many top jewelry factories, repair shops, and custom design studios use this specific jewelry laser welding machine.

Performance & Core Features

- High-Precision Welding: I find it performs accurate micro-welding on metals like platinum, gold, silver, titanium, and stainless steel. Material loss is very low, less than 1mm.

- Seamless Welds: It works well for detailed items like chains, prongs, claws, and bezels.

- Low Heat Zone: This feature helps protect gemstones that are sensitive to heat. I think this is a great benefit.

- Easy Operation: It uses a touchscreen. The system remembers parameters, checks itself for issues, and lets you watch the process in real time. I suggest trying out the touchscreen; it seems straightforward.

- Safety: It meets CE & ISO9001 standards. It includes double safety shields, an emergency stop button, and a password lock.

Typical Applications

- Gold ring shank resizing: It makes clean welds that are almost invisible. The process takes just seconds.

- Prong retipping/repair: It avoids heat damage to nearby gemstones.

- Fine chain repair: It reliably fixes very thin chain links.

- Custom engraving: You can get an optional part for surface marking and making custom designs. I recommend considering this if you offer customization.

Herolaser HERO-LJW200: A Precise Jewelry Laser Welder from China

I find the Herolaser HERO-LJW200 is an advanced jewelry laser welder made for custom jewelry work. Shenzhen Herolaser Equipment Co., Ltd designs and makes it. From my experience, they are a top laser company with over 18 years in the business. They export to more than 60 countries.

Advanced Welding Features

- Wobble Welding Head: Herolaser developed this unique head. I believe it helps create cleaner, stronger welds. It also reduces the chance of burning through, which is useful for thin jewelry.

- Dual Operation Modes: You can choose continuous or modulation modes. This works for different metals and types of welds.

- Gap Tolerance: It handles gaps up to 0.5 mm. This is important for precise jewelry work.

- Penetration Data: A 500W model can weld 0.5–0.8 mm deep on stainless or carbon steel. If you need deeper welds, I suggest choosing a higher wattage model.

- Supported Materials: It works with many metals like gold, silver, titanium, nickel, tin, copper, aluminum, and their alloys.

- No Consumables: You don’t need extra materials like welding rods. This saves money and makes it easier to use.

Jewelry & Industry Applications

- Custom Jewelry Making: It welds precious metals smoothly with very little change to the shape.

- Repairs: You can fix tiny cracks in gold rings. It also joins delicate silver chains seamlessly.

- Other Uses: I see it being useful for making eyewear, watches, fine hardware, craft gifts, and small medical tools.

Summary

Each of these top jewelry laser welders from China combines precision, durability, and value — empowering jewelers to deliver stunning craftsmanship with confidence. Whether you’re starting a new custom jewelry business or upgrading your workshop, investing in the right machine can transform your productivity and creativity. Choose the welder that fits your needs, and take your jewelry artistry to the next level. The perfect tool is just one decision away — are you ready to make it yours? For more details about jewelry laser welder or to get a quote, contact us today!

Recent Comments