Precision is key in jewelry welding, and the right tool can make all the difference. Jewelry laser welders with cameras are changing the game, offering advanced accuracy and streamlined processes. In this article, we’ll highlight the top 3 jewelry laser welders with camera systems that can elevate your craftsmanship and improve efficiency. Let’s dive in!

MaxWave MW-QW200 Jewelry Laser Welder

From my experience, the MaxWave MW-QW200 Jewelry Laser Welder offers great precision, speed, and flexibility. I believe it’s a top choice for professional jewelry workshops.

Great Precision and Flexibility

It features a very fine beam diameter of 0.01 mm. This allows for detailed welding. I find this useful for working with complex and delicate jewelry designs. You can make precise welds on tiny or complex patterns. The results compare well to the work of skilled artisans.

High Performance and Speed

Laser welding is up to 10 times faster than traditional soldering, significantly boosting productivity. The air-cooled system allows for continuous use without the need for lengthy cool-downs. Plus, it’s built to last, with a lifespan of over 100,000 hours.

Technical Specifications at a Glance

- Output Power: You can adjust it from 60–200W

- Peak Power: Up to 2000W

- Pulse Width: 0.2–15ms gives you fine control

- Beam Quality (BPP): 1–2mm × mrad ensures focused, reliable energy delivery

- Weight: 40 kg means it has a compact, space-saving design

Design, Maintenance, and Being Eco-Friendly

The MaxWave MW-QW series jewelry laser welder shines with a smart, modular design that’s compact enough for any small workshop but built for serious performance. Its rock-solid stability ensures smooth operation even during long hours of work. If one module ever needs attention, no problem — the others keep running without a hitch, and replacing a single module is quick and hassle-free. That means less downtime, lower maintenance costs, and more peace of mind. The simplified optical path keeps everything aligned and easy to maintain.

It’s tough enough to handle shipping without a scratch and ready to go straight out of the box. Even better, its eco-conscious design allows you to replace only what’s necessary — reducing waste and saving money at the same time.

How It Works Efficiently

MaxWave manufactures its lasers in-house, guaranteeing consistent power and long-term reliability. With almost no consumable parts, it significantly reduces ongoing costs and downtime, which I find incredibly beneficial. The stable optical path ensures high-quality, precise welds with minimal energy loss, resulting in strong, durable results every time.

Pricing

Our MaxWave MW-QW series jewelry laser welder are priced between $3,700 and $4,900, depending on the selected power configuration. This flexible pricing allows jewelers and manufacturers to choose the ideal model based on their specific workload and material requirements. Whether you’re handling delicate repairs or high-precision production, there’s a configuration that meets your needs—without compromising on quality or performance.

Customization and Support

MaxWave offers customization options for functions, laser components, and even external branding, making it perfect for individual clients or distributors. I appreciate that their direct after-sales and technical support comes from their own team, ensuring fast service without the delays of third-party involvement.

LaserStar 993 iWeld Benchtop Laser Welder (60W)

I find the LaserStar 993 iWeld Benchtop Laser Welder is a strong and useful tool for jewelers. It helps achieve precise, dependable results. It’s made in the USA. This welder, which includes a camera, is built for frequent, demanding work.

Key Technical Specifications

- Laser Power: 60W with a peak output of 11,000W

- Pulse Energy: Up to 180 joules, adjustable pulse duration (0.1–30 ms)

- Pulse Frequency: Ranges from 0.5 to 50 Hz

- Wavelength: 1064 nm (Nd:YAG technology)

- Dimensions & Weight: 33”L x 21”W x 16”H; weighs 151 lbs (68.5 kg)

- Chamber Size: 10” x 20” x 9” for comfortable working

- Cooling: Forced air system

Standout Features I Like for Jewelers

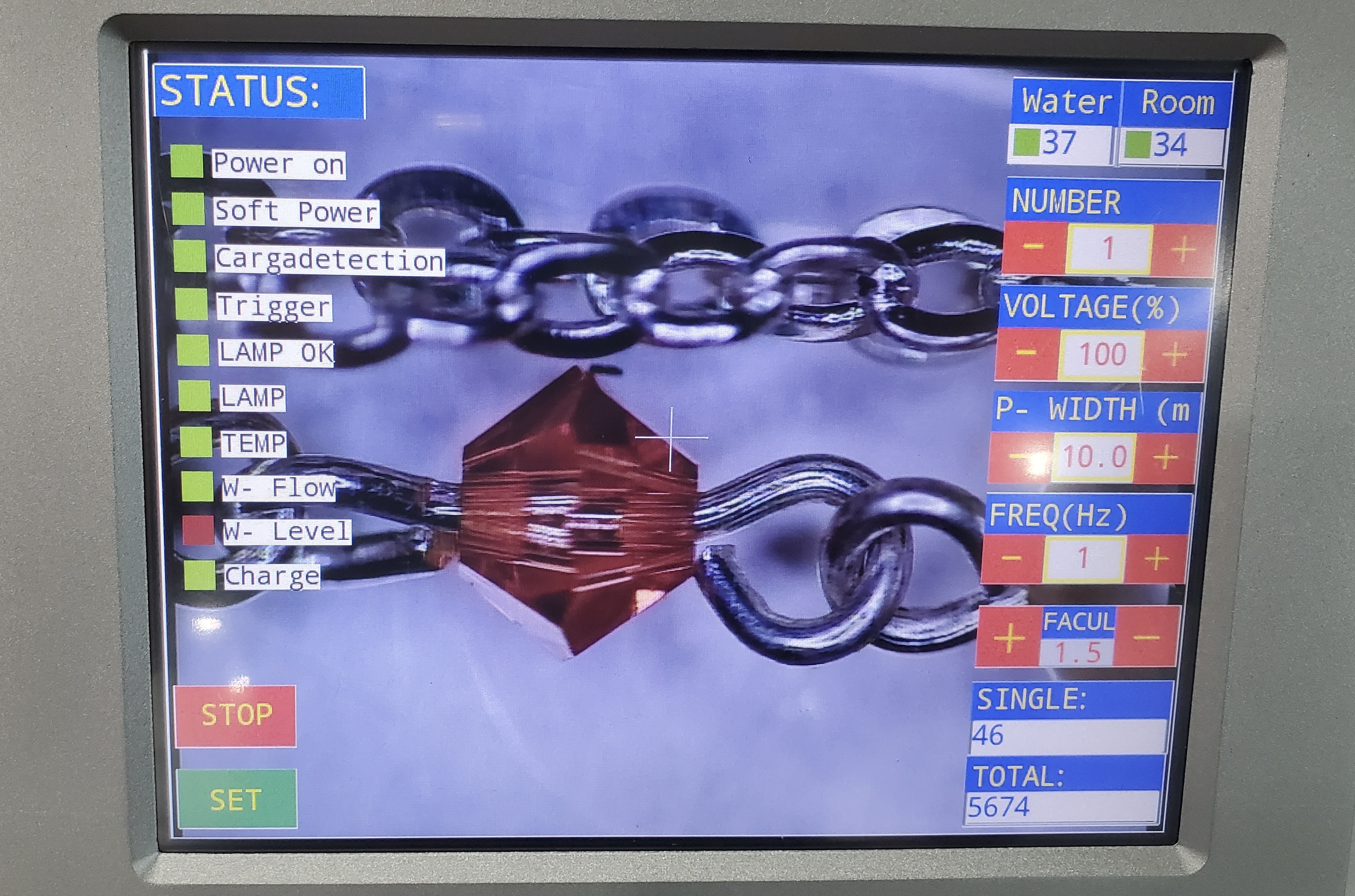

This jewelry laser welder features an HD 4K 8MP camera, letting you connect via HDMI for live viewing, perfect for taking notes and recording progress. Its 15x stereo microscope offers detailed visibility, making precision tasks easier. A 7-inch digital display clearly shows settings and current status, while bright LED daylight bulbs illuminate the work area. Controls are user-friendly, with an exterior touchscreen and an internal joystick, plus the ability to store up to 79 memory settings for added convenience.

Pricing and Value

With a market price of approximately $17,500, this high-performance model is proudly made in the USA—reflecting top-tier craftsmanship, strict quality standards, and trusted reliability recognized worldwide.

Key Advantages of the LaserStar 993 iWeld

- Industry Reputation: It’s known for having the highest peak power for its type.

- Help with Precision: The live 4K camera view improves training. It also helps with record-keeping and checking quality. I think this feature is a significant benefit.

- Who It’s For: It’s made for jewelers, dental/ortho labs, eyewear repair shops, prototype makers, and general job shops.

Why I Suggest the LaserStar 993 iWeld for Jewelry

Built for strength and reliability, the LaserStar 993 iWeld Benchtop Laser Welder is ready for long hours of precise jewelry work. Its spacious chamber gives you a comfortable, efficient workspace, while the easy-to-connect camera lets you monitor your process in real time and even record your work for future reference. Whether you’re working with gold, silver, platinum, or various alloys, this jewelry laser welder handles a wide range of precious metals with ease.

In my opinion, this benchtop jewelry laser welder is a great pick for jewelry professionals. It’s also good for repair experts who need a flexible and powerful tool.

ZAC 60W Jewelry Laser Welder (with Camera)

I think the ZAC 60W Jewelry Laser Welder with Camera is a dependable tool for professional jewelry welding and repair. It uses a strong 1064nm YAG laser source. This benchtop model gives you 60W of power, which I find is enough for most standard jewelry tasks. Some versions offer up to 150W. Its pulse energy goes up to 40 Joules. You can adjust the pulse frequency between 1 and 10 Hz for detailed work.

Key Technical Specifications

- Wavelength: 1064nm YAG laser

- Power Output: 60W base (up to 150W in some versions)

- Pulse Energy: Up to 40 Joules

- Pulse Frequency: 1–10 Hz, adjustable

- Pulse Width: 0.1–15 ms (adjustable for different tasks)

- Spot Size: 0.1–3.0 mm, adjustable for various jewelry work

- Repeat Accuracy: ±0.002mm

Precision Welding for Diverse Jewelry Applications

The ZAC jewelry laser welder is perfect for intricate tasks like soldering and repairing gold, silver, platinum, and 24K gold pieces. It’s ideal for delicate jobs like resizing rings, creating fine chains, and connecting small links. You can also repair prongs and stone settings without disturbing the stones, making it great for precision work. Whether you’re crafting custom jewelry, micro-joining, or restoring antiques, it ensures seamless results with invisible joints.

The microscope and CCD camera system give you a clear, real-time view of the welding area. From my experience, this feature is vital when you work on tiny parts. It helps ensure great accuracy. It also limits the heat spread, which protects sensitive gemstones.

Advantages in Jewelry Making and Repair

It offering high precision that minimizes the risk of melting surrounding metal and cuts down on post-weld finishing work. Its small heat-affected zone makes it especially safe for working near gemstones or intricate details. Fast heating and cooling cycles significantly reduce welding time, boosting efficiency whether you’re handling repairs or crafting new pieces. The free-movement design allows jewelers to hold items by hand under the microscope for perfect alignment and control. Plus, its compact size and user-friendly interface make it a perfect fit for standard jewelry workbenches or even small retail shops.

Example Workflow for Jewelers

- Place the jewelry piece under the microscope. Use the camera feed for careful alignment.

- Set the best pulse energy, frequency, and spot size based on the metal type and thickness.

- Use the live camera view to position the weld. Then trigger the laser for a clean join.

- Check the weld. Let it cool quickly. Perform minimal finishing for a seamless result.

Support, Service, and Comparable Models

It isn’t just a jewelry laser welder — it’s your reliable workshop companion. Priced between $3,700 and $4,900 depending on power, it comes with a 1-year warranty and full technical and video support in multiple languages to make your training smooth and stress-free. Many users compare it to well-known models like the iWeld 993 Series or Leikang 60W, but the ZAC stands out for its exceptional precision, great value, and built-in camera system that makes every weld easier and more accurate.

Pricing

You can usually find the ZAC 60W Jewelry Laser Welder with Camera priced between $3,000 and $8,000. The final cost depends on the configuration and the service packages included.

Summary

Choosing the right jewelry laser welder can transform the way you work, elevating both the quality of your creations and your overall efficiency. With powerful camera systems and advanced precision, these machines are designed to give you the control and accuracy you need for flawless results every time. Ready to take your jewelry-making to the next level? Invest in the best, and watch your craft reach new heights. Don’t settle for less—make your next weld your best weld! For more details about jewelry laser welder or to get a quote, contact us today!

Recent Comments